Econwatson

Well-Known Member

- Joined

- 26/11/12

- Messages

- 309

- Reaction score

- 56

If all you were wanting to do is find out the alcohol content, I always thought it would be cool if you could modify a breathaliser, and get an alcohol reading that way.

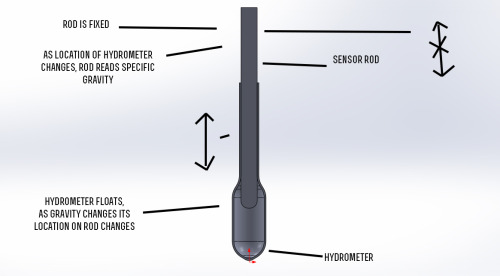

Unfortunately Beerbug won't hold pressure, and calcs for escaping Co2 would really be come complex if we start presurising things at different temps, so densimetry or refraction are the only 2 methods I can see workingRdeVjun said:Beaten by MB, nevertheless IMO your most worthwhile solution is probably in densimetry. Unfortunately gross mass and volume sensing at this scale can be fiddly, it can be susceptible to environmental fluctuations such as temperature, humidity and electrical noise, plus accounting for evaporation and respiration is difficult, and that's presuming you can source affordable sensors and interface with the required precision.

Yes, densimetry would also have value in the mash and boil, so a solution could be more universal than just monitoring the ferment.

The Beerbug could be helpful- hope it doesn't rain on your parade too much?

This bubble counter might also be useful if you're wanting to monitor respiration rate, I never pursued it after seeing the light with cling film displacing my airlock bubblers.

In my day job we explored densimetry for continuous monitoring of suspended sediment in waterways, but sadly it never got very far off the drawing board due to the expense and experimental nature- for a short term project we couldn't risk the time it would take to develop a solution, so just reverted to conventional pumping samplers and event sampling etc., however I still feel it has some merit, particularly where remoteness or access is an issue.

HTH!

Why? CO2 loss = [CO2 concentration difference (e.g., micromoles CO2/mol air, i.e., ppm)] X [flow rate (e.g., mol air/minute)]. If flow is measured on a volume basis, it's easy to correct for pressure and temperature (moles/volume = n/V = P/RT). And since CO2 conc in the fermenter will very rapidly reach 100% whereas CO2 outside is negligible (~400 ppm), you could get away with only measuring flow rate.MastersBrewery said:...calcs for escaping Co2 would really be come complex if we start presurising things at different temps...

Enter your email address to join: