TwoCrows

Well-Known Member

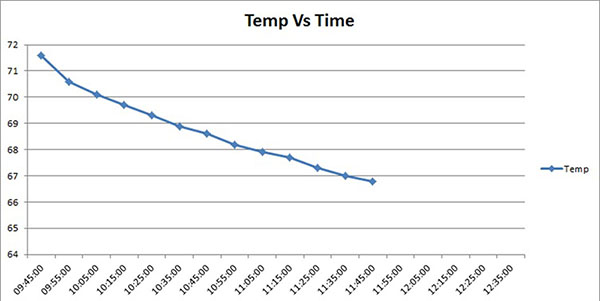

Some eskies have more thermal mass. This means you would need to pre heat for a longer period of time or start at a higher temperature and allow the insulation to store/ remove water temp.

I haveand have used a 60ltr techni ice cooler and it sucks away all my heat as a mash tun. I scrapped it.

I haveand have used a 60ltr techni ice cooler and it sucks away all my heat as a mash tun. I scrapped it.