You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Guide To Keg Forced Carbonation.

- Thread starter als_world

- Start date

Help Support Australia & New Zealand Homebrewing Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Spork

Well-Known Member

- Joined

- 19/4/11

- Messages

- 989

- Reaction score

- 5

Have done this a few times now, as I ran low on grain and my consumption outpaced production. :huh:

I CC my beer at 0.5c, so after filtering into keg I can force carb easily with the near freezing liquid absorbing the bubbles really well.

Haven't got the method perfect yet, and hope to soon get ahead in my production so I can resume slow carbing on a spare line while serving form other 3 kegs, but for times of crisis (no beer on tap!) this is a winner.

I CC my beer at 0.5c, so after filtering into keg I can force carb easily with the near freezing liquid absorbing the bubbles really well.

Haven't got the method perfect yet, and hope to soon get ahead in my production so I can resume slow carbing on a spare line while serving form other 3 kegs, but for times of crisis (no beer on tap!) this is a winner.

If you want to force carb a warm keg of beer say around 22 deg Celsius.

What would be the best way to do this?

I have seen the force carb charts but they don't tell you how long you need to do this for?

This is for my dad who used to force carb by chilling with his chest freezer (kegerator) but that died and he bought a ice chiller, so the kegs stay warm.

Any help on this would be great, we currently need to carb a cider in a 9L keg and an ale an normal corny keg.

Cheers

What would be the best way to do this?

I have seen the force carb charts but they don't tell you how long you need to do this for?

This is for my dad who used to force carb by chilling with his chest freezer (kegerator) but that died and he bought a ice chiller, so the kegs stay warm.

Any help on this would be great, we currently need to carb a cider in a 9L keg and an ale an normal corny keg.

Cheers

slash22000

Stereotypical Lupulin Addict

- Joined

- 2/7/12

- Messages

- 887

- Reaction score

- 233

So I got greedy and tried this method rather than my normal "Set to 30 PSI and wait 2 days" approach.

Went well until Step 6 "Turn the gas off at the regulator". Ended up blowing beer right up the line into the regulator. I turned it off straight away and blew the beer out of the regulator with the gas. It still seems to work. Hopefully?

Not sure what I did wrong. Maybe I am cursed. "Turn the gas off at the regulator" - does this mean at the actual regulator itself, or at the bottle? Can somebody clarify exactly what this means? I'm sure I've just done something ******* stupid since it seems to work for everybody else. I am not actually sure exactly what I did, the stress and freak out of seeing beer shoot up the gas line has erased my memory. :wacko:

Went well until Step 6 "Turn the gas off at the regulator". Ended up blowing beer right up the line into the regulator. I turned it off straight away and blew the beer out of the regulator with the gas. It still seems to work. Hopefully?

Not sure what I did wrong. Maybe I am cursed. "Turn the gas off at the regulator" - does this mean at the actual regulator itself, or at the bottle? Can somebody clarify exactly what this means? I'm sure I've just done something ******* stupid since it seems to work for everybody else. I am not actually sure exactly what I did, the stress and freak out of seeing beer shoot up the gas line has erased my memory. :wacko:

glenwal

aus Bier hergestellt

- Joined

- 8/12/10

- Messages

- 812

- Reaction score

- 29

You didn't put a non return valve in.Not sure what I did wrong.

bignath

"Grains don't grow up to be chips, son"

- Joined

- 3/11/08

- Messages

- 2,611

- Reaction score

- 40

Went well until Step 6 "Turn the gas off at the regulator". Ended up blowing beer right up the line into the regulator. I turned it off straight away and blew the beer out of the regulator with the gas. It still seems to work. Hopefully?

You'll need to replace the seal inside the regulator.

I did the same thing once only, when i first started kegging (it's a common problem) and of course your reg will still work, but over time, the liquid that was inside your regulator will start rusting all the parts inside the reg. Trust me, get a new rebuild kit. Craftbrewer sell them. Others probably do too, but i KNOW they sell them.

Not sure what I did wrong. Maybe I am cursed. "Turn the gas off at the regulator" - does this mean at the actual regulator itself, or at the bottle?

At the bottle.

Think about it. If you leave the bottle with the valve open 'cause you've been carbing the keg, and then just turn the regulator down, all the pressure inside the keg will go back into the regulator because now all of a sudden, the pressure going into the keg is less than what's in the keg already. Instant problem.

Turn the bottle off without touching the regulator, and then continue as normal per step 6. (shake the **** out of the keg and watch the pressure guage drop).

Answers in red.

slash22000

Stereotypical Lupulin Addict

- Joined

- 2/7/12

- Messages

- 887

- Reaction score

- 233

Thanks for that Big Nath.

I'm assuming the kit you're talking about is this one? How about the "WARNING" part there? Not going to blow myself up am I? :mellow:

I'll be buying a no-return valve ASAP for sure. I didn't even know they existed until the posters above mentioned them. You'd think that's the sort of thing that should come standard. Ah well, live and learn.

All that said, the force carbing did work, aside from the "ruining my regulator" part!

I'm assuming the kit you're talking about is this one? How about the "WARNING" part there? Not going to blow myself up am I? :mellow:

I'll be buying a no-return valve ASAP for sure. I didn't even know they existed until the posters above mentioned them. You'd think that's the sort of thing that should come standard. Ah well, live and learn.

All that said, the force carbing did work, aside from the "ruining my regulator" part!

Truman42

Well-Known Member

- Joined

- 31/7/11

- Messages

- 3,973

- Reaction score

- 608

Just a quick queston, but if I use a NRV in my gas line how do I read the gas pressue in my keg? Wont the NRV stop the gas pressure from coming back into the regulator??

on a diferent note, I went to put 40 PSi into my keg to let it sit for 24 hours and read the wrong part of the gauge. I ended up trying to put 40 BAR which is 58 PSI but the regulator stopped at about 35 BAR and started stuttering the reg releif valve.

Ive just let it sit all weekend and will see how it pours tonight.

on a diferent note, I went to put 40 PSi into my keg to let it sit for 24 hours and read the wrong part of the gauge. I ended up trying to put 40 BAR which is 58 PSI but the regulator stopped at about 35 BAR and started stuttering the reg releif valve.

Ive just let it sit all weekend and will see how it pours tonight.

Nick JD

Blah Blah Blah

- Joined

- 4/11/08

- Messages

- 7,322

- Reaction score

- 456

Just a quick queston, but if I use a NRV in my gas line how do I read the gas pressue in my keg? Wont the NRV stop the gas pressure from coming back into the regulator??

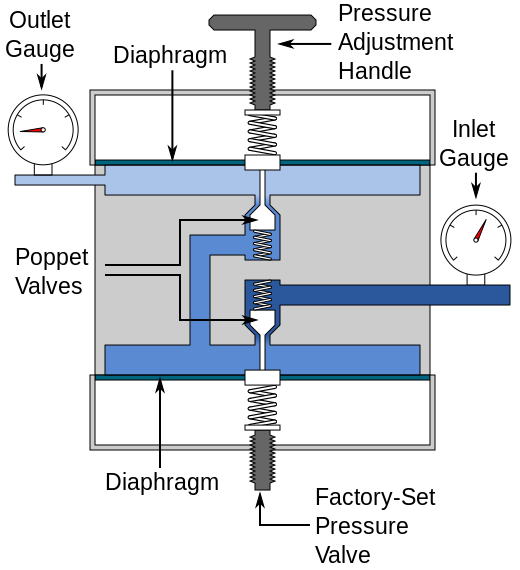

Non return valve is betwen the kegs and the regulator. Regulator gauge reads the regulator pressure it's "giving", not it's "given".

Truman42

Well-Known Member

- Joined

- 31/7/11

- Messages

- 3,973

- Reaction score

- 608

Thanks for that informative diagram Nick.

But Ive read carbing how tos that say on day 3 connect up your regulator and check to see what pressure is in the keg. I still dont get how I can do this espeically as you say the reg gauge shows reg presure its giving not what its being given?

But Ive read carbing how tos that say on day 3 connect up your regulator and check to see what pressure is in the keg. I still dont get how I can do this espeically as you say the reg gauge shows reg presure its giving not what its being given?

GalBrew

Well-Known Member

Thanks for that informative diagram Nick.

But Ive read carbing how tos that say on day 3 connect up your regulator and check to see what pressure is in the keg. I still dont get how I can do this espeically as you say the reg gauge shows reg presure its giving not what its being given?

I don't see how hooking up a keg to your regulator will tell you the pressure in the keg? The regulator regulates gas pressure out not in. You may have the bottle off and some residual pressure within the reg that shows up on the second dial, but that is not keg pressure. You can buy a thing that you plug into your keg that has a dial on it that will tell you keg pressure (I think craftbrewer sells one) but that is a different thing altogether. Also if you have a check valve nothing should be running back to the regulator from the keg at all.

kahlerisms

Well-Known Member

Does this method need any adjusting if you're carbing a keg that's maybe half full or less?

jaymzica

Well-Known Member

- Joined

- 3/4/13

- Messages

- 81

- Reaction score

- 14

raven19 said:I had to gas up a keg of golden ale for cricket mates, I simply went 300kPa for 24hrs in the fridge.

Normally I never touch my reg settings.

A non return valve is a must imo - cheap insurance for your reg.

Ive got no idea when it comes to force carbing. some how ive managed to carb 2 kegs so far, but that's rocking them, adjusting gas ect, leaving for a day or so. I might just try that 300kpa for 24hrs next time

ash2

Well-Known Member

- Joined

- 27/8/12

- Messages

- 143

- Reaction score

- 21

When storing a brew in a keg does it matter what temp it is,will your beer age in a keg like it does in bottles ?Beers2U said:Any tips on kegging a brew and storing it for a later date, i only have a small fridge in my shed which can only hold one keg, i have only started kegging recently, so would like to know if storing is possible

Guys,

Sorry new to the kegging game and about to christen my new kegs. Stupid question but just wanted to be sure.

I have just done my first CC and its currently at 4 degrees. I am assuming i can skip the 24-48 hr wait for the temp to fall to 4 degree in the keg and just carb straight away after transfer as the beer temp is at 4 degrees. Didnt know if the actual keg also needs to be cold? Was going to sterilise, transfer and carb...

Thanks

Doug

**EDIT** Think Spork answered my question above... **

Sorry new to the kegging game and about to christen my new kegs. Stupid question but just wanted to be sure.

I have just done my first CC and its currently at 4 degrees. I am assuming i can skip the 24-48 hr wait for the temp to fall to 4 degree in the keg and just carb straight away after transfer as the beer temp is at 4 degrees. Didnt know if the actual keg also needs to be cold? Was going to sterilise, transfer and carb...

Thanks

Doug

**EDIT** Think Spork answered my question above... **

Steve

On the back bloody porch!

- Joined

- 10/6/05

- Messages

- 4,656

- Reaction score

- 101

The keg itself doesn't need to be cold just the beer....so yes sanitise that first and then transfer and carb.Doug2232 said:Guys,

Sorry new to the kegging game and about to christen my new kegs. Stupid question but just wanted to be sure.

I have just done my first CC and its currently at 4 degrees. I am assuming i can skip the 24-48 hr wait for the temp to fall to 4 degree in the keg and just carb straight away after transfer as the beer temp is at 4 degrees. Didnt know if the actual keg also needs to be cold? Was going to sterilise, transfer and carb...

Thanks

Doug

Good to see Ross is still happy to guide people through this over the phone. I remember stuffing up my first force carb and he was straight on the phone. I over carbed it!!!

Cheers

Steve

roastinrich

Well-Known Member

Has anyone ever experienced off flavours from force carbing using contaminated co2. I've been getting mine refilled from an aquarium guy and sometimes my beers have a funky taste. Can't figure out if it's from the co2, or chlorine in the top up water ( k&k).

Similar threads

- Replies

- 20

- Views

- 11K

- Replies

- 8

- Views

- 4K