iralosavic

Well-Known Member

- Joined

- 17/10/11

- Messages

- 1,131

- Reaction score

- 21

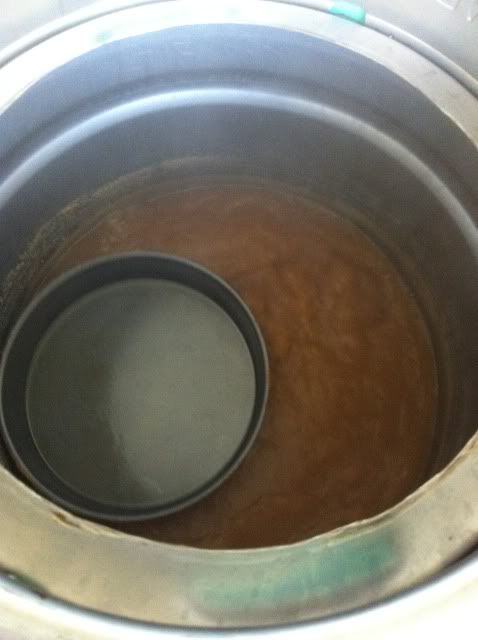

Would a teflon cake tin be suitable as a floatie or would it have to be stainless?

To be honest I'd personally rather use stainless or even aluminium, but given the only tins I had in the kitchen were non-stick that's what I've been using so far - and with no obvious issues. The coating is designed to be both water and heat resistant, but I wouldn't take this option if stainless were available. We just don't know if any of the teflon or other chemicals are being released and what affect they would have on our health.

The best thing about using a floating tin is that you don't get any returning condensate (which can put the volatiles causing DMS back into your beer instead of sending it into the atomsphere) and it's about as cheap and easy a solution as you can get.