I see. Well, the first photo you've got there is of a self-tuning PID controller, the second is of a mashmate which is an on-off controller. An on-off controller is pretty straightforward - the element is on when the temperature is below the setpoint, of when it's above. A PID controller, along with most other types of controller besides on-off, adjusts the duty cycle of the heating element - turns it on for a few cycles, off for a few - so that the heat put out by the element can be varied. The PID controller specifically has its output power determined by a combination of the size of the error (the difference between the setpoint and the current temp), the derivitive (the speed that it's changing) and the integral of the error (the sum of all previous sampled errors over time). This allows for finer control over the temperature, and can, in well tuned systems, result in fast rise time (initial heating when you turn it on or change the temp), low or even zero overshoot, fast settling time (how long it takes to stop over and undershooting), and better steady state stability and accuracy (once it's reached the setpoint, it stays there). There are some caveats though. On-off control works reasonably well, with the main limitation being how long it takes the heat you put in to affect the temperature read by the sensor. PID control needs to be tuned, and expects the system it's controlling to be linear and time invariant (this means that you've always got the same amount of water in it, the ambient temperature is the same, air movements etc all remain reasonably constant). Such a controller will perform very differently with a small batch as compared to a large one. There are smarter control systems that can deal with this sort of thing on the fly, but they're much harder to come by, because they're more difficult to understand and design.

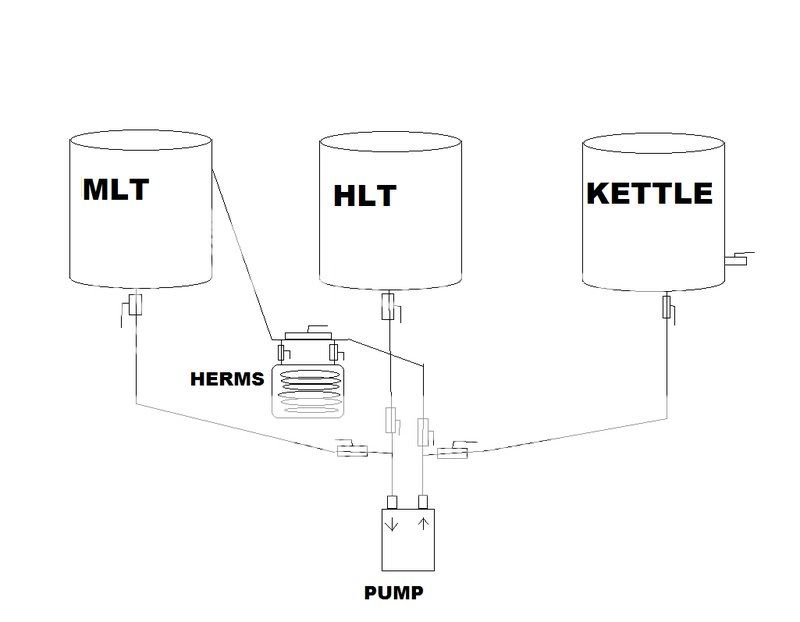

All of that aside, a PID controller will still likely perform better, once tuned for an average water volume, than an on-off controller. That isn't to say that the on-off controller won't be satisfactory, and since they're cheaper, it might be hard to argue with on-off control. There is another important consideration though - for a HERMS system, I understand that you've got a pump recirculating the wort through a copper coil submerged in the HLT, which is full of water at some higher temperature, and the pump is either shut off, or has its flow diverted with a solenoid valve, so that the recirculated wort doesn't flow through the HLT coil, correct? In this case, it has to be on-off control (for the pump and/or the solendoid), unless you have some means of varying the flow in small steps, like zizzle's wiper-motor-ball-valve contraption, or an expensive flow control valve, or a pump that is happy with a variable duty cycle. Even then, you would need a complex, double input, dual loop system model to account for the fact that you've got a variable HLT temp and a variable flow rate. The maths gets pretty ugly.

If it were me, I'd go for a PID controller on the HLT's element, and a mashmate on-off controller for the HERMS recirc pump/valve. If it's a RIMS, not a HERMS, a PID loop on the RIMS element wouldn't go astray but again, expect variable performance with variable system conditions.