pcqypcqy

Well-Known Member

- Joined

- 23/5/15

- Messages

- 872

- Reaction score

- 393

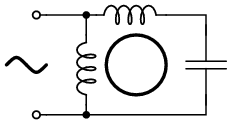

You say you rewired it... Did you touch the starting winding at all, where that tape is?

It should have four wires plus earth (two of which are the starter windings, 90° out of phase).

We didn't go into the metal pump housing itself, just attached a new lead to the wires that were in that little plastic housing at the back.