I only made 3 batches of beer on the big system this year, the rest (maybe 30?) were done on the little system.lael said:Cool vid Kev. How often do you use this system vs your larger system now?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

QldKev's New Biab With Internal Rims

- Thread starter QldKev

- Start date

Help Support Australia & New Zealand Homebrewing Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

It makes brew day a lot more fun and easy. I enjoy that there is not a lot to setup and clean. Allows me to experiment with a lot of recipes. Also I can knock out a brew pretty fast by backing up the heating with an immersion element. About 15mins and I'm at strike temp.

Don't get me wrong both systems are great. If I was time poor, then the 3V punching out 4 x 28L cubes at a time would be my choice. But at the moment I'm enjoying more brew days.

Don't get me wrong both systems are great. If I was time poor, then the 3V punching out 4 x 28L cubes at a time would be my choice. But at the moment I'm enjoying more brew days.

Moad

Well-Known Member

This has inspired me QK, I too have the 3v rig but it isn't really feasible to do less than a double batch. My list of "to brew" experimental batches is growing and this may be the answer.

I'll likely PM you or start another thread but for now I have a few quick questions:

Firstly, what would the total cost be approximately? I need a project but if is is going to run up around $500 or so then I may be better off picking of a grainfather...

Would a little brown pump be sufficient? You helped me build an old version of this rig and it seemed to do the job on it. I would imagine the pump you use may be cost prohibitive this time around. If it is a necessity then I will start on other parts of the project while scraping some coin together.

Is the benefit of mathos controller that you can program step mashes? I'll do some more reading on this.

I see you have used a keg, what would be the best alternative for the outside pot? What size would be best?

I avoided welding last time but it looks like I will have to find someone to do some simple welds for me.

Would you do anything differently if you were to build from scratch again?

Cheers,

Nick.

I'll likely PM you or start another thread but for now I have a few quick questions:

Firstly, what would the total cost be approximately? I need a project but if is is going to run up around $500 or so then I may be better off picking of a grainfather...

Would a little brown pump be sufficient? You helped me build an old version of this rig and it seemed to do the job on it. I would imagine the pump you use may be cost prohibitive this time around. If it is a necessity then I will start on other parts of the project while scraping some coin together.

Is the benefit of mathos controller that you can program step mashes? I'll do some more reading on this.

I see you have used a keg, what would be the best alternative for the outside pot? What size would be best?

I avoided welding last time but it looks like I will have to find someone to do some simple welds for me.

Would you do anything differently if you were to build from scratch again?

Cheers,

Nick.

If you ever get up this way look me up and we can throw a brew through on mine. Best way to see if you like it in action.Moad said:This has inspired me QK, I too have the 3v rig but it isn't really feasible to do less than a double batch. My list of "to brew" experimental batches is growing and this may be the answer.

I'll likely PM you or start another thread but for now I have a few quick questions:

Firstly, what would the total cost be approximately?

Total cost, I didn't spend much on it.

the element was a cheap uxcel $8 (about $20 inc enclosures, cord, etc)

keg i had

plumbing fittings I had

2m of the cheap $5.95 silicone hose

pump was about $80

big W pot, $20

stainless bolts/bar/rod $20-$30

insulation was what ever I had on hand

matho's controller was about $200. (a budget sestos setup would be a bit over $50)

I need a project but if is is going to run up around $500 or so then I may be better off picking of a grainfather...

It's always more fun to build things, but I think the grainfather for $1K is great buying. Once they piss off that dual element setup and throw a basic pid in there it will be awesome. The bonus is it looks more bllingy. Also you can get the other head for it making it dual purpose should you ever go that way.

Would a little brown pump be sufficient? You helped me build an old version of this rig and it seemed to do the job on it. I would imagine the pump you use may be cost prohibitive this time around. If it is a necessity then I will start on other parts of the project while scraping some coin together.

It wold do the job, but if you can get one of the kaixin mp-15 for about $60 which would help ensure the element doesn't get burnt.

Is the benefit of mathos controller that you can program step mashes? I'll do some more reading on this.

Yep, pid and it supports multiple steps, and mainly for the bling. Any pid even with manual steps would be great. So a sestos pid is still a great way, but without the multiple steps.

I see you have used a keg, what would be the best alternative for the outside pot? What size would be best?

Kegs are great. Our metal recyclers sells stainless for $2 kg. A keg is approx 13kg. Just got to find one who doesn't make up a random price for it on the day. Otherwise any 50-60L pot.

I avoided welding last time but it looks like I will have to find someone to do some simple welds for me.

No real need to weld. The rod for the inner pot handle could just be bent around the bolt, and done up with some wide washers. The upper support could be done the same was a braumeister does with a U type shape rod for the inner pot to sit one.

Would you do anything differently if you were to build from scratch again?

I still want to swap the old plumbing parts for some bling stainless camlocks. One day

Possibly get some blingy looking insulation for it

Not knocking matho's controller, but in hind site I wished I went the EmbeddedControlConcepts setup.

Also a skinnier taller inner and outer pot, with the inner one over 20L would be great.

Cheers,

Nick.

Moad

Well-Known Member

Awesome thanks mate, the element was my next question... I thought the pump would be more than that too.

I'll go over yours in a bit more detail and no doubt have some more questions.

Edit: why bcs? Bling factor? Seems overkill on this build

I'll be up that way in March but not sure of itinerary yet, could be a goer. Thanks for the offer

I'll go over yours in a bit more detail and no doubt have some more questions.

Edit: why bcs? Bling factor? Seems overkill on this build

I'll be up that way in March but not sure of itinerary yet, could be a goer. Thanks for the offer

Here's a couple of links for the mp-15 pump, both have the newer high temp head

Craftbrewer, includes plug $70

National Home Brew, need your own plug $65

(These are just 2 suppliers I use, there are more ones out there)

Also do you have a pump on the existing system that you could port between the 2 setups?

BCS, mainly bling and so I can monitor it from my office

Craftbrewer, includes plug $70

National Home Brew, need your own plug $65

(These are just 2 suppliers I use, there are more ones out there)

Also do you have a pump on the existing system that you could port between the 2 setups?

BCS, mainly bling and so I can monitor it from my office

Moad

Well-Known Member

hahaha I thought so re:BCS. I am looking into it, may be a little over my head without significant research. If I was tackling an electronics project like that it would more likely be something like kegbot to monitor keg levels.

I actually have a spare March pump that came with the 3v so will use that!

With the elements, anything in particular I should be looking at? Putting a 20A circuit in the garage this weekend if that makes a difference.

Will start looking at some pots

I actually have a spare March pump that came with the 3v so will use that!

With the elements, anything in particular I should be looking at? Putting a 20A circuit in the garage this weekend if that makes a difference.

Will start looking at some pots

I went for a cheap $7 uxcell 2,000w element. It was just a concept to see how it went so I got the cheapest. I went for 2,000w so by the time I add the pump and controller I am still under the 10amp for a standard GPO. Only thing is these elements have gone up a lot since then, making other cheap water system elements look more attractive. With 2,000w it does take a bit to get to the boil, and I have needed to wrap it in 3 layers of insulation to get a decent boil off amount. So 2,000w is the min and not the best. Depending on power on the day I often throw in an immersion element to speed things up. With both running it is fast, but once I hit the boil I only run the 2,000w element.

With 20amps you have a few choices, you could get a big element and also a voltage controller. Then you can crank it up for ramping to strike and to the boil etc, and once you hit the boil drop the volts until you get a nice boil. The Camco from Amazon and ebay have a good reputation. If it was mine I would do the volt controller ($10 to $50) and a Camco 3500w ultra low density (approx $30odd)

5star also does some decent 2400w elements in weld or weldless that are reliable. 2400w weldless, or 3600w weldless. I run a couple of the 2400w weldless for another hobby and they have been great, and being stainless housing they look bling too.

Your sparky will know, but ensure they use a decent heavy duty cable that meets or exceeds the power rating of the element.

With 20amps you have a few choices, you could get a big element and also a voltage controller. Then you can crank it up for ramping to strike and to the boil etc, and once you hit the boil drop the volts until you get a nice boil. The Camco from Amazon and ebay have a good reputation. If it was mine I would do the volt controller ($10 to $50) and a Camco 3500w ultra low density (approx $30odd)

5star also does some decent 2400w elements in weld or weldless that are reliable. 2400w weldless, or 3600w weldless. I run a couple of the 2400w weldless for another hobby and they have been great, and being stainless housing they look bling too.

Your sparky will know, but ensure they use a decent heavy duty cable that meets or exceeds the power rating of the element.

I have recently had to size some elements for my boil kettle and found the following calculation useful. It does assume ideal conditions and does not account for losses but it has served me well. Cant figure out how to link the excel but you'll get the idea. We know how much energy is required to evaporate 1kg water @100 degrees so you just need to enter your boil off rate required. I usually aim for 12% so for a standard single batch your 2Kw element is right in the ball park as you have found. Have you measured your boil off % with just the 2kw in a single batch Kev?

[SIZE=medium]Heat Transfer Calculations[/SIZE]

[SIZE=medium]hfg - water[/SIZE] [SIZE=medium]2257[/SIZE] [SIZE=medium]kj/kg[/SIZE]

[SIZE=medium]Target Evaporation[/SIZE] [SIZE=medium]12%[/SIZE] [SIZE=medium]per hour[/SIZE]

[SIZE=medium]Start Volume[/SIZE] [SIZE=medium]28[/SIZE] [SIZE=medium]L[/SIZE]

[SIZE=medium]Evaporation Volume[/SIZE] [SIZE=medium]3.36[/SIZE] [SIZE=medium]L[/SIZE]

[SIZE=medium]Energy Required[/SIZE] [SIZE=medium]7583.52[/SIZE] [SIZE=medium]kj [/SIZE]

[SIZE=medium]Power required to evap in 60 mins[/SIZE] [SIZE=medium]2.106533[/SIZE] [SIZE=medium]kW[/SIZE]

[SIZE=medium]edit: bugger, table doesn't come in.[/SIZE]

[SIZE=medium]Heat Transfer Calculations[/SIZE]

[SIZE=medium]hfg - water[/SIZE] [SIZE=medium]2257[/SIZE] [SIZE=medium]kj/kg[/SIZE]

[SIZE=medium]Target Evaporation[/SIZE] [SIZE=medium]12%[/SIZE] [SIZE=medium]per hour[/SIZE]

[SIZE=medium]Start Volume[/SIZE] [SIZE=medium]28[/SIZE] [SIZE=medium]L[/SIZE]

[SIZE=medium]Evaporation Volume[/SIZE] [SIZE=medium]3.36[/SIZE] [SIZE=medium]L[/SIZE]

[SIZE=medium]Energy Required[/SIZE] [SIZE=medium]7583.52[/SIZE] [SIZE=medium]kj [/SIZE]

[SIZE=medium]Power required to evap in 60 mins[/SIZE] [SIZE=medium]2.106533[/SIZE] [SIZE=medium]kW[/SIZE]

[SIZE=medium]edit: bugger, table doesn't come in.[/SIZE]

Moad

Well-Known Member

Throw in Google sheets or drop box?

Thanks Kev I'll hold off on any more questions for now.

edit: I know it isn't a PID but I have a spare flashed STC that I could use to control element for step mashing... thoughts?

Thanks Kev I'll hold off on any more questions for now.

edit: I know it isn't a PID but I have a spare flashed STC that I could use to control element for step mashing... thoughts?

I often start with a 32L and end at 28L, which works out at 12% boil offhusky said:I have recently had to size some elements for my boil kettle and found the following calculation useful. It does assume ideal conditions and does not account for losses but it has served me well. Cant figure out how to link the excel but you'll get the idea. We know how much energy is required to evaporate 1kg water @100 degrees so you just need to enter your boil off rate required. I usually aim for 12% so for a standard single batch your 2Kw element is right in the ball park as you have found. Have you measured your boil off % with just the 2kw in a single batch Kev?

[SIZE=medium]Heat Transfer Calculations[/SIZE]

[SIZE=medium]hfg - water[/SIZE] [SIZE=medium]2257[/SIZE] [SIZE=medium]kj/kg[/SIZE]

[SIZE=medium]Target Evaporation[/SIZE] [SIZE=medium]12%[/SIZE] [SIZE=medium]per hour[/SIZE]

[SIZE=medium]Start Volume[/SIZE] [SIZE=medium]28[/SIZE] [SIZE=medium]L[/SIZE]

[SIZE=medium]Evaporation Volume[/SIZE] [SIZE=medium]3.36[/SIZE] [SIZE=medium]L[/SIZE]

[SIZE=medium]Energy Required[/SIZE] [SIZE=medium]7583.52[/SIZE] [SIZE=medium]kj [/SIZE]

[SIZE=medium]Power required to evap in 60 mins[/SIZE] [SIZE=medium]2.106533[/SIZE] [SIZE=medium]kW[/SIZE]

[SIZE=medium]edit: bugger, table doesn't come in.[/SIZE]

Moad said:Throw in Google sheets or drop box?

Thanks Kev I'll hold off on any more questions for now.

edit: I know it isn't a PID but I have a spare flashed STC that I could use to control element for step mashing... thoughts?

I think a STC is a great start up controller, heaps better than manually trying to do it.

Moad

Well-Known Member

Great, I can even save multiple profiles with the STC+ firmware.

I note earlier you said the probe is fine below the inner pot, is this still your thinking? Why not on the return?

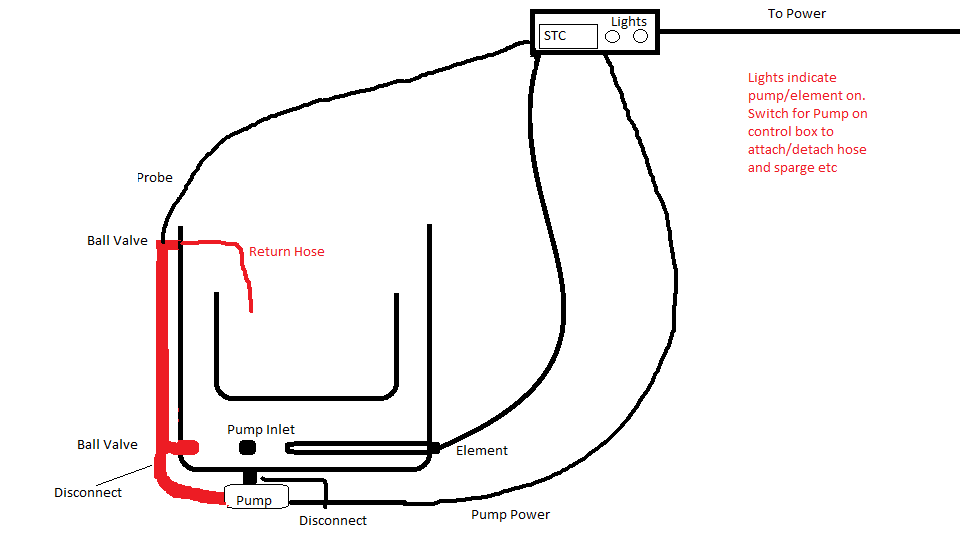

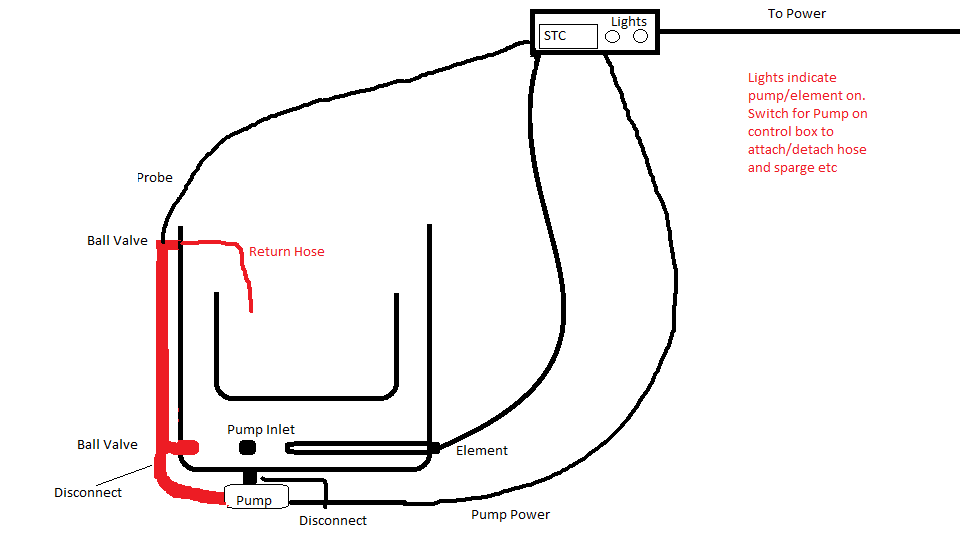

Nothing really different here but these are my thoughts, would like to have a little control box. The pump isn't neccessarily below the pot either, my paint skills are piss weak.

What would you suggest for quick disconnects on the liquid lines, I'll add power cable disconnects on the element and pump lines as well as something for the probe so I can strip it right down for cleaning/storage.

edit: I did say I wouldn't ask any more questions but I'm all pumped (<-- see what I did there) for another project now.

I note earlier you said the probe is fine below the inner pot, is this still your thinking? Why not on the return?

Nothing really different here but these are my thoughts, would like to have a little control box. The pump isn't neccessarily below the pot either, my paint skills are piss weak.

What would you suggest for quick disconnects on the liquid lines, I'll add power cable disconnects on the element and pump lines as well as something for the probe so I can strip it right down for cleaning/storage.

edit: I did say I wouldn't ask any more questions but I'm all pumped (<-- see what I did there) for another project now.

The idea of the temperature probe is to be in the hottest part of the wort as the enzyme activity occurs in the wort. So in the middle of the grain bed would be a bad place to monitor it as the return wort could far exceed this temperature especially when ramping up temperatures. On a traditional mash tun the return after any HX is normally the best spot as it is an easy spot to pick up that warm wort. But to clarify my temp pickup on my 3V is from the HERMS output as it exits the coil, and not after the return hose as it could potentially lose a small amount of heat into the hose. Realistically we are talking minute amounts of heat difference in the 2 spots.

In the case of our 1V since the sump area (area below pot) is free moving wort that is getting recirculated by the lower pump return I think it would potentially be the best spot as it is in direct contact to the heated wort at the hottest point. By putting it at the top of the return hose you stand to lose some heat from the wort prior to that point. Once again I think the heat loss would be very minimal so both positions make a great spot. Not that it is a huge concern, but should the pump fail then the probe in the sump would still detect the temperatures there and prevent potential boiling.

For the plumbing I like the camlocks I have on my 3V, and one day will upgrade my 1V with them. I got them from T&S valves. I've noticed these days most sponsors and also ebay has them. There is no set specification for them, so camlocks from different suppliers may not fit each other. I know the ebay ones will not fit the T&S valves ones.

I agree with the idea of being able to unplug everything from the system. The more crap you can unplug and get out the way the easier cleanups are. On my 1V all hoses, pump, controller, etc all get stored in it between uses.

Feel free to ask question, it's what we are here for

In the case of our 1V since the sump area (area below pot) is free moving wort that is getting recirculated by the lower pump return I think it would potentially be the best spot as it is in direct contact to the heated wort at the hottest point. By putting it at the top of the return hose you stand to lose some heat from the wort prior to that point. Once again I think the heat loss would be very minimal so both positions make a great spot. Not that it is a huge concern, but should the pump fail then the probe in the sump would still detect the temperatures there and prevent potential boiling.

For the plumbing I like the camlocks I have on my 3V, and one day will upgrade my 1V with them. I got them from T&S valves. I've noticed these days most sponsors and also ebay has them. There is no set specification for them, so camlocks from different suppliers may not fit each other. I know the ebay ones will not fit the T&S valves ones.

I agree with the idea of being able to unplug everything from the system. The more crap you can unplug and get out the way the easier cleanups are. On my 1V all hoses, pump, controller, etc all get stored in it between uses.

Feel free to ask question, it's what we are here for

Also talking about heating elements, I noticed

20L Braumeister (25L wort) = 2,000w

50L Braumeister (55L wort) = 3,200w

30L Grainfather (?? wort) = 2,000w

Also the shape of the pot will make a difference to the amount of heating required. A skinny tall pot will require less heat than a wider one.

20L Braumeister (25L wort) = 2,000w

50L Braumeister (55L wort) = 3,200w

30L Grainfather (?? wort) = 2,000w

Also the shape of the pot will make a difference to the amount of heating required. A skinny tall pot will require less heat than a wider one.

Moad

Well-Known Member

Cheers mate, I am thinking a 2400w water element. The braumeister elements have alot of surface area to avoid scorching etc

and regarding the return, makes complete sense. Another benefit of the dual return.

and regarding the return, makes complete sense. Another benefit of the dual return.

Moad

Well-Known Member

I was thinking I could use it for step mashing but it is only one step per hour unfortunately. Might still go with mathos or look at bcs. Will depend on budget once I tally it all up

Also dont forget the Auber ramp/soak pid, it's what I'm running on my 3V. But it's not the most user friendly thing to play with.Moad said:I was thinking I could use it for step mashing but it is only one step per hour unfortunately. Might still go with mathos or look at bcs. Will depend on budget once I tally it all up

Similar threads

- Replies

- 18

- Views

- 2K

- Replies

- 0

- Views

- 2K

Equipment For Sale

FS: 160L 3v electric herms - Newcastle

- Replies

- 0

- Views

- 994