b_thomas

Well-Known Member

- Joined

- 4/2/08

- Messages

- 202

- Reaction score

- 0

Have finally moved away from the bottles on to kegging (scored a fire extinguisher yesterday from work). I've got a question regarding force cabonation that's hopefully easily answered.

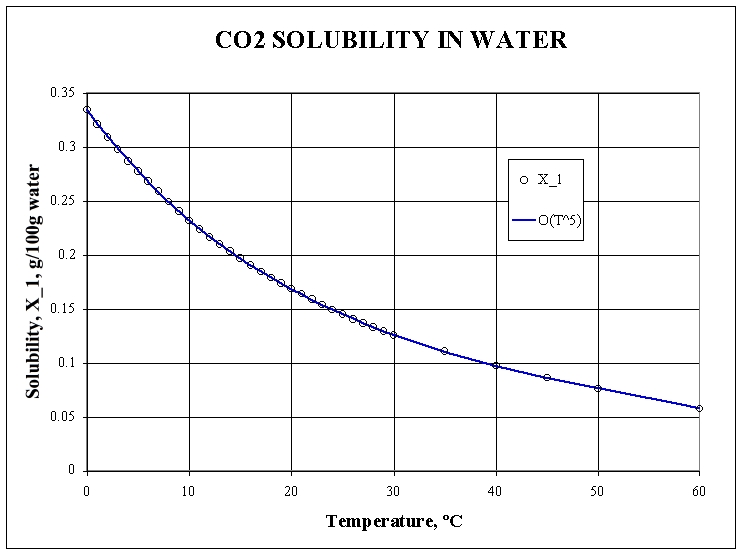

If I force carb using the slow method at a higher temperature (ie. 18c) and then drop down to serving temperature (ie. 5-6c) will the CO2 already absorbed at that higher temperature cause the beer to become more "fizzy"?

I'm assuming I would need to reduce the PSI once the beer is at serving temp if I want to maintain the same volume of CO2 in solution it's just the transition from the warmer temp that I don't want to bugger up.

I guess I can always burp the keg if it is too "fizzy".

If I force carb using the slow method at a higher temperature (ie. 18c) and then drop down to serving temperature (ie. 5-6c) will the CO2 already absorbed at that higher temperature cause the beer to become more "fizzy"?

I'm assuming I would need to reduce the PSI once the beer is at serving temp if I want to maintain the same volume of CO2 in solution it's just the transition from the warmer temp that I don't want to bugger up.

I guess I can always burp the keg if it is too "fizzy".