I'm 24 and aussie and even I use imperial sometimes... just seem easy to say 'about an inch' than 'two or three centimeters'. People look at me funny when I'm discribing something and use imperial and metric in the same sentence: "yeah the table is about a meter high, and the distance shaft to shaft is about 8in" lol.

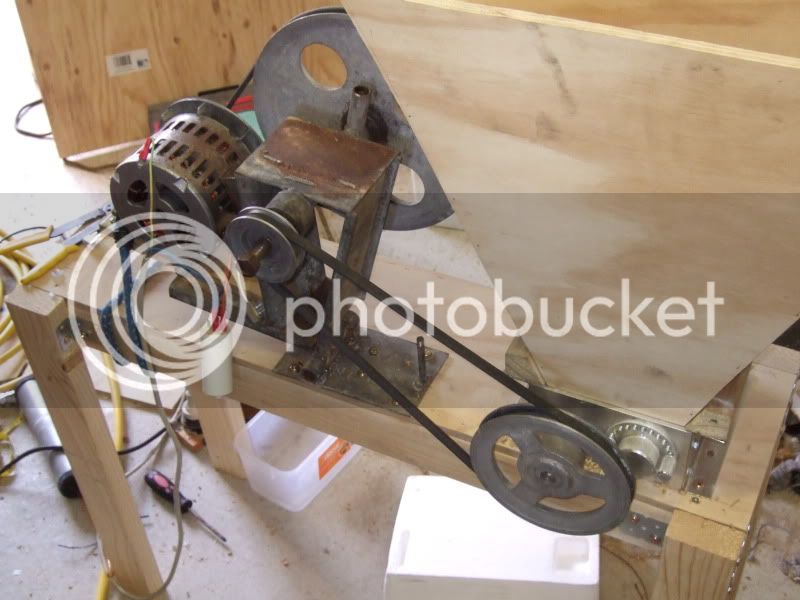

And while we're in a mill motorizing thread, I'll post a pic of mine. A bit simpler, and a heap more exxy (im one of those guys that doesn't have access to any machining equipment more complex/expensive than a drill)

View attachment 29541

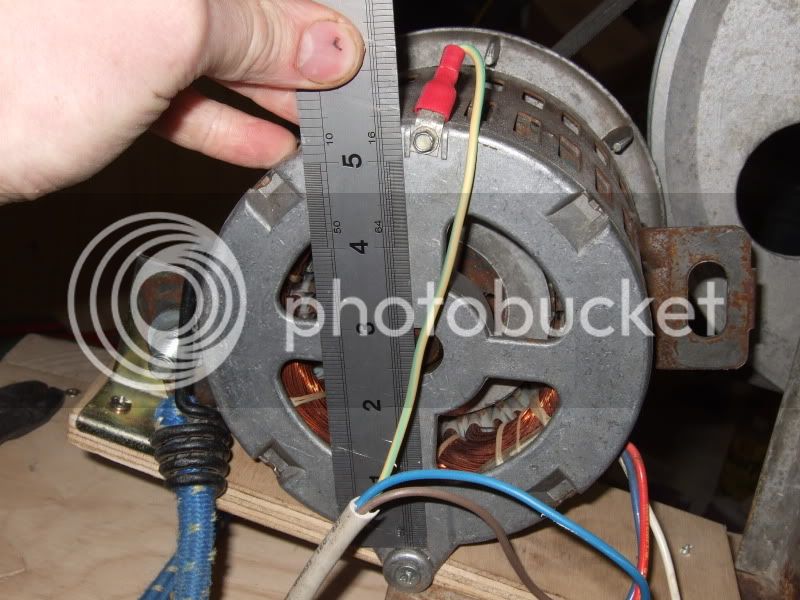

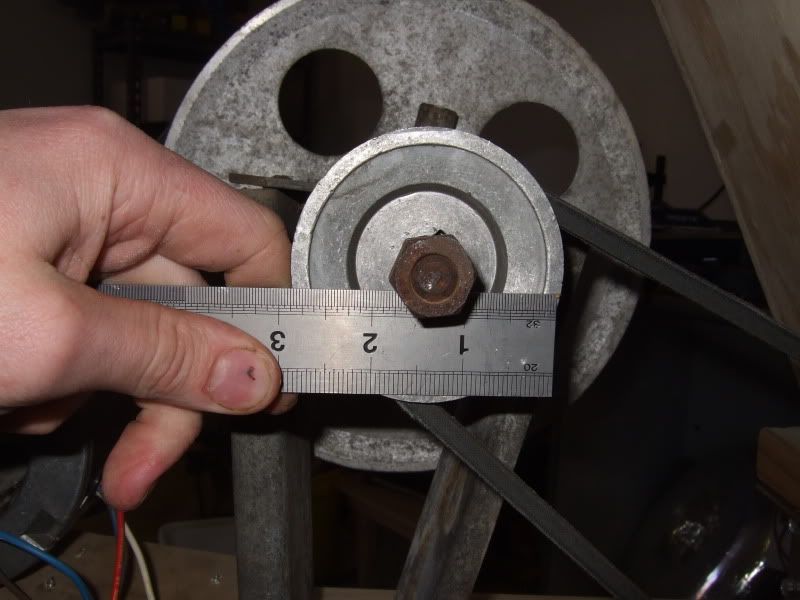

It's a 920rpm 3/4hp cap start motor with a 1.25" pulley onto the millmaster with a 10" pulley, custom 12x4 bore and key for a cool $55 B) runs like a dream. Uncovered pulleys because I like living on the edge - theyre against a wall now.