DigitalGiraffe

Well-Known Member

- Joined

- 19/8/10

- Messages

- 98

- Reaction score

- 18

Hey guys,

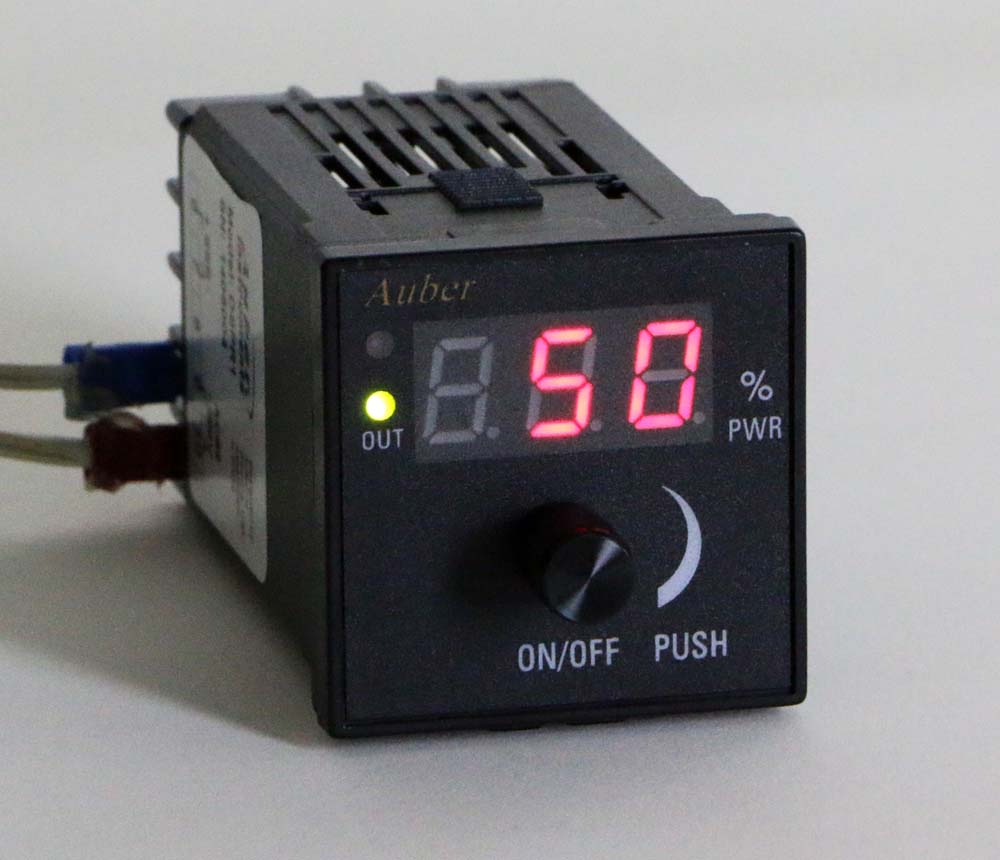

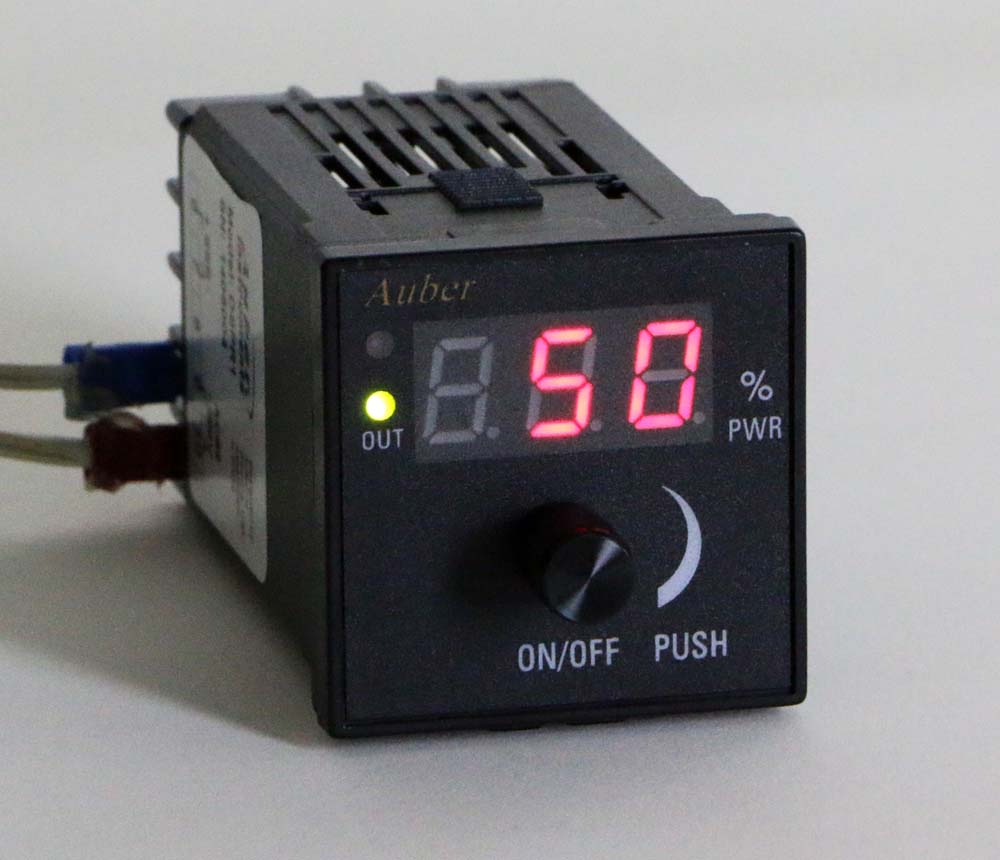

So I'm finally at the point where I need to make a call on an element for my system (Brew area in garage is taking shape and its time for electrician quotes). I have the 2200w KK and it just does the job, the boil gets very slow after a while. I'm thinking about the 5* 2400w as it would probably give me the kick that I need or my other option is going 15A circuit and running the 5* 3600w. I am kind of leaning to this but I know it will be too much power so I was thinking about running it through one of these guys. Is there anywhere in Australia that offers a similar product? Does anyone here use one? I have seen a lot of similar units with a temp prob attached but I don't really need this feature.

So I'm finally at the point where I need to make a call on an element for my system (Brew area in garage is taking shape and its time for electrician quotes). I have the 2200w KK and it just does the job, the boil gets very slow after a while. I'm thinking about the 5* 2400w as it would probably give me the kick that I need or my other option is going 15A circuit and running the 5* 3600w. I am kind of leaning to this but I know it will be too much power so I was thinking about running it through one of these guys. Is there anywhere in Australia that offers a similar product? Does anyone here use one? I have seen a lot of similar units with a temp prob attached but I don't really need this feature.