Impy

Well-Known Member

- Joined

- 30/12/09

- Messages

- 130

- Reaction score

- 12

So... putting together an electric brew kettle is a lesson in patience.

I've got 90% of the parts required to put together the AG set up I've decided to go with. I don't have the space or motivation for a 2 or 3 vessel system so single vessel BIAB seemed like the smart choice.

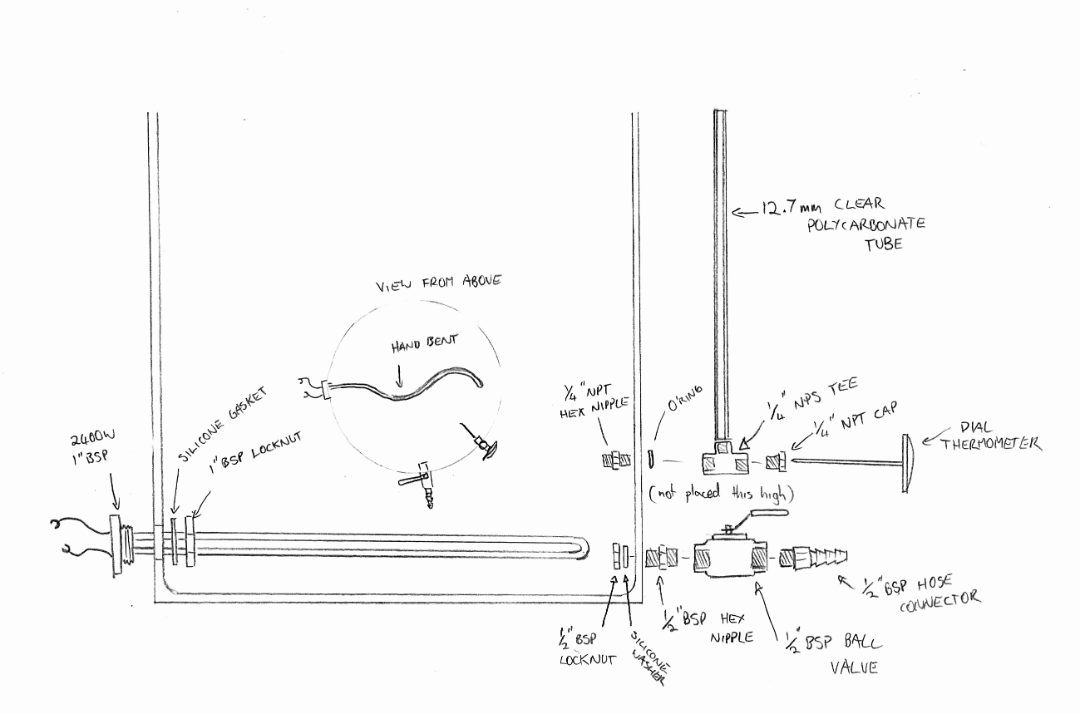

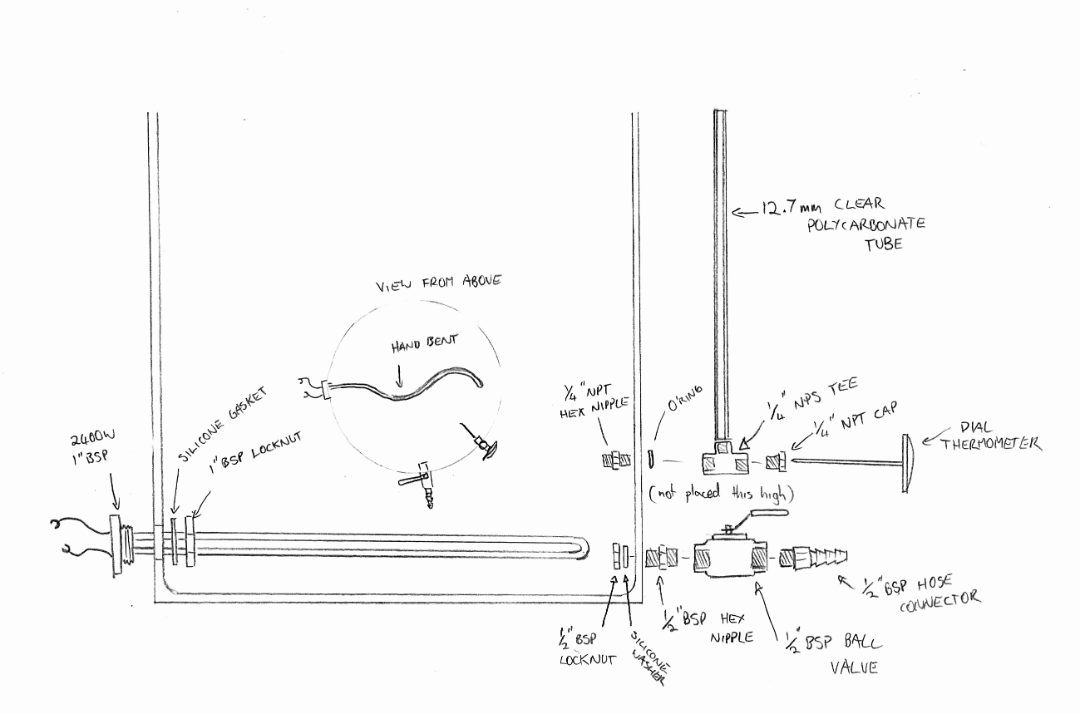

Here is a rough sketch of how the system will go together.

I sourced the pot from Kitchenware Direct It's not the ideal shape since it's wider than it is tall, but it's nothing a bit of insulation can't fix.

IMPORTANT: If you buy from here, get a silicone baking mat as well. You'll need it for making gaskets and pushing the total cost over $100 gets you free shipping!

The most time consuming part was looking for stainless steel parts and the required washers. All up I spent the better part of a day driving around buying the parts I needed and still didn't manage to get everything.

I sourced my stainless plumbing parts from T&S Valves in Ingleburn NSW Seriously, if you're in Sydney don't even bother looking anywhere else, I did, and it was just a waste of time. These guys have all the things you need and huge amounts of stock (no frustrating "out of stock" delays)

Where I SHOULD have gotten the stainless washers from is a place just down the road from T&S called Fred Tapping but they have a $25 minimum Eftpos and the washers I needed were only $5 (the $5 was spend on a bacon and egg McMuffin on the drive there... damn it). So when you make the trip, HAVE CASH and you can get most of your stuff in one go.

Buying from T&S meant the parts were cheap compared to getting it online at Craft Brewer ($27 for all required stainless plumbing parts compared to ~$50 + postage @ Craft Brewer)

Since the pot is aluminium, drilling the holes wasn't too hard and didn't really require any out of the ordinary bits (neighbour had a tradesmans drill + a large collection of bits). All holes were drilled a little smaller than required, and slowly filed larger so the fits were nice and tight.

I took a bit of a gamble with the element. For a low low $36 inc postage I picked up this 2400W 1" BSP element. It didn't look hardened like other ones i've seen so even though it's too long to fit in the pot, I bought it to try and bend it to fit. And I think it's worked..

Obviously I won't know until it's wired, but it was very malleable and bent over my knee with ease. I took it slow, and made sure I didn't apply too much pressure to any one place, so fingers crossed I've just discovered a stupendously cheap Aussie supplier for electric brewing elements.

Rubber washers... oh how I hate thee! Finding silicone washers and orings is a F%#@ng nightmare!! I caved and bought some from Craft Brewer which meant they were probably a little expensive, but at least they had them.

Next steps are to recover the table from my wifes competing hobby and get it assembled.

Shopping list so far

Chef Inox 50L Aluminium stock pot ($100)

2400Watt 1" BSP Element ($36.00)

Silicone bakeware for making gaskets ($3.95)

1/2" BSP SS 2 part ball valve ($9.60)

1/2" BSP SS hose tail ($3.44)

1/2" BSP SS hex nipple ($2.32)

1/2" BSP SS locknut ($2.00)

1" BSP SS locknut ($2.48)

1/4" NPT SS TEE ($2.60)

1/4" NPT SS cap ($1.58)

1/4" NPT SS hex nipple ($1.20)

12.7mm outer diameter polycarbonate tube ($20)

3x SS washers to fit 1/4" NPT ($2)

1x SS washer to fit 1/2" BSP ($1)

1x SS eyebolt & nut ($5)

Silicone washers and orings ($9.30)

Teflon tape (40c)

Cost so far: $202.87

I'll update with how the assembly and leaktesting goes as well as the final components I need (insulation, gangbox, wiring etc) but so far I'm enjoying my foot in the door to all grain!

I've got 90% of the parts required to put together the AG set up I've decided to go with. I don't have the space or motivation for a 2 or 3 vessel system so single vessel BIAB seemed like the smart choice.

Here is a rough sketch of how the system will go together.

I sourced the pot from Kitchenware Direct It's not the ideal shape since it's wider than it is tall, but it's nothing a bit of insulation can't fix.

IMPORTANT: If you buy from here, get a silicone baking mat as well. You'll need it for making gaskets and pushing the total cost over $100 gets you free shipping!

The most time consuming part was looking for stainless steel parts and the required washers. All up I spent the better part of a day driving around buying the parts I needed and still didn't manage to get everything.

I sourced my stainless plumbing parts from T&S Valves in Ingleburn NSW Seriously, if you're in Sydney don't even bother looking anywhere else, I did, and it was just a waste of time. These guys have all the things you need and huge amounts of stock (no frustrating "out of stock" delays)

Where I SHOULD have gotten the stainless washers from is a place just down the road from T&S called Fred Tapping but they have a $25 minimum Eftpos and the washers I needed were only $5 (the $5 was spend on a bacon and egg McMuffin on the drive there... damn it). So when you make the trip, HAVE CASH and you can get most of your stuff in one go.

Buying from T&S meant the parts were cheap compared to getting it online at Craft Brewer ($27 for all required stainless plumbing parts compared to ~$50 + postage @ Craft Brewer)

Since the pot is aluminium, drilling the holes wasn't too hard and didn't really require any out of the ordinary bits (neighbour had a tradesmans drill + a large collection of bits). All holes were drilled a little smaller than required, and slowly filed larger so the fits were nice and tight.

I took a bit of a gamble with the element. For a low low $36 inc postage I picked up this 2400W 1" BSP element. It didn't look hardened like other ones i've seen so even though it's too long to fit in the pot, I bought it to try and bend it to fit. And I think it's worked..

Obviously I won't know until it's wired, but it was very malleable and bent over my knee with ease. I took it slow, and made sure I didn't apply too much pressure to any one place, so fingers crossed I've just discovered a stupendously cheap Aussie supplier for electric brewing elements.

Rubber washers... oh how I hate thee! Finding silicone washers and orings is a F%#@ng nightmare!! I caved and bought some from Craft Brewer which meant they were probably a little expensive, but at least they had them.

Next steps are to recover the table from my wifes competing hobby and get it assembled.

Shopping list so far

Chef Inox 50L Aluminium stock pot ($100)

2400Watt 1" BSP Element ($36.00)

Silicone bakeware for making gaskets ($3.95)

1/2" BSP SS 2 part ball valve ($9.60)

1/2" BSP SS hose tail ($3.44)

1/2" BSP SS hex nipple ($2.32)

1/2" BSP SS locknut ($2.00)

1" BSP SS locknut ($2.48)

1/4" NPT SS TEE ($2.60)

1/4" NPT SS cap ($1.58)

1/4" NPT SS hex nipple ($1.20)

12.7mm outer diameter polycarbonate tube ($20)

3x SS washers to fit 1/4" NPT ($2)

1x SS washer to fit 1/2" BSP ($1)

1x SS eyebolt & nut ($5)

Silicone washers and orings ($9.30)

Teflon tape (40c)

Cost so far: $202.87

I'll update with how the assembly and leaktesting goes as well as the final components I need (insulation, gangbox, wiring etc) but so far I'm enjoying my foot in the door to all grain!