Moad

Well-Known Member

Just hope to hell they don't get your order wrong. Was a real pain getting a refund for $17 of parts they didn't send

did you raise the issue via ebay/paypal resolution or just message them?Moad said:Just hope to hell they don't get your order wrong. Was a real pain getting a refund for $17 of parts they didn't send

It almost seems like a way of business for many of these import sellers, 2014online included. A couple of the others are AUWarehouse and av-rf.SBOB said:did you raise the issue via ebay/paypal resolution or just message them?

Getting a full refund from china sellers is pretty easy with an 'item not received' claim (though if you received most, this is kind of a dick move), and partial refunds are usually ok if you just spell out the basic request via the ebay resolution process... Rarely do you get an email response, just a paypal refund appearing (at least in my experience)

I've done many an item not received claim for items coming from China without issue for things arriving broken, completely wrong order or just never turn up at all

You can have the brewery, I want to have that Lamaze dog toy there.Benn said:Can I have it?

No that would require me to total up the cost...I am way past that...Benn said:Can I have it?

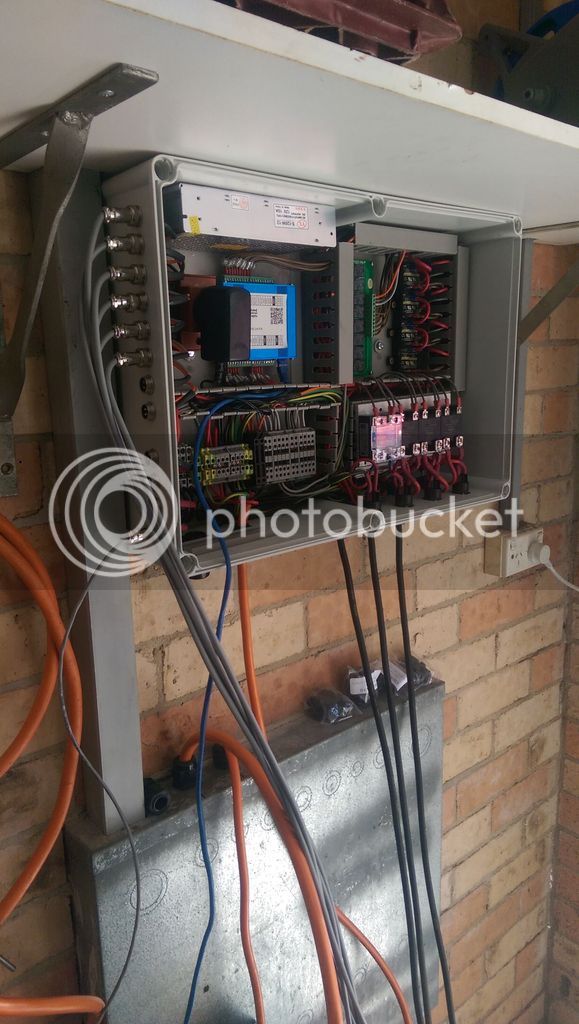

It looks a little untidy because I left the cover plate off where they are all channeled. I owe lots of beer to my mate for putting the electrical stuff together, and my other mate who helped with the plumbing and stand, and Bruce (Tex n Oz) for the welding.SBOB said:nice panel wiring