So my simple, cheap, milling setup is going back to the drawing boards and I'll be sourcing the same motor for electric bikes that others have used.

GT

Doesn't even crack one grain?

I'd guess that your power supply is as soft as fresh sh!t.

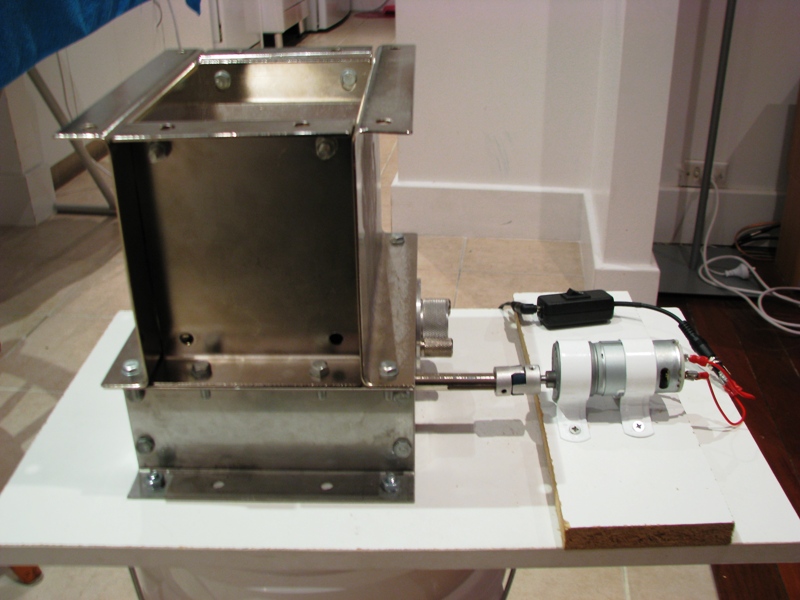

Sorry, haven't read any of you're previous posts, but the gearheadmotor looks like a Jaycar YG-2738??

The 55kg per cm torque, 160RPM one?

What's the diameter of the millmaster rollers?

If, for example, the rollers are 2" diameter, their radius is 2.5cm, so 55kg/2.5 = 22kg of crushing force

IF your power supply could handle the current draw.

Which is 14 amps(or 14000 mA -- what does your supply say?) at full-load (170 Watts - almost 1/4 horsepower), a wall-wart aint gonna cut it, either is a Car Battery charger.

The motor needs almost half an amp( 6 Watts) with

no load at all, just spinning in the air.

A modified PC switch-mode power supply? ---- maybe, if it doesn't freak out at the surge current when the motor is switched on.

If you have a fully charged car battery nearby, hook that up with some heavy duty wiring(not the stuff in your photo, which would probably smoke and melt at 14 amps) and a couple of decent aligator clips to connect to the battery terminals, get rid of the wimpy switch and the 3.5mm plug which will probably weld itself together at 14amps... and I think you'll be a happy man

). I am hopeless with making things, so dad made it for me, which is really nice of him, and I give him kudos for it.

). I am hopeless with making things, so dad made it for me, which is really nice of him, and I give him kudos for it.