You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

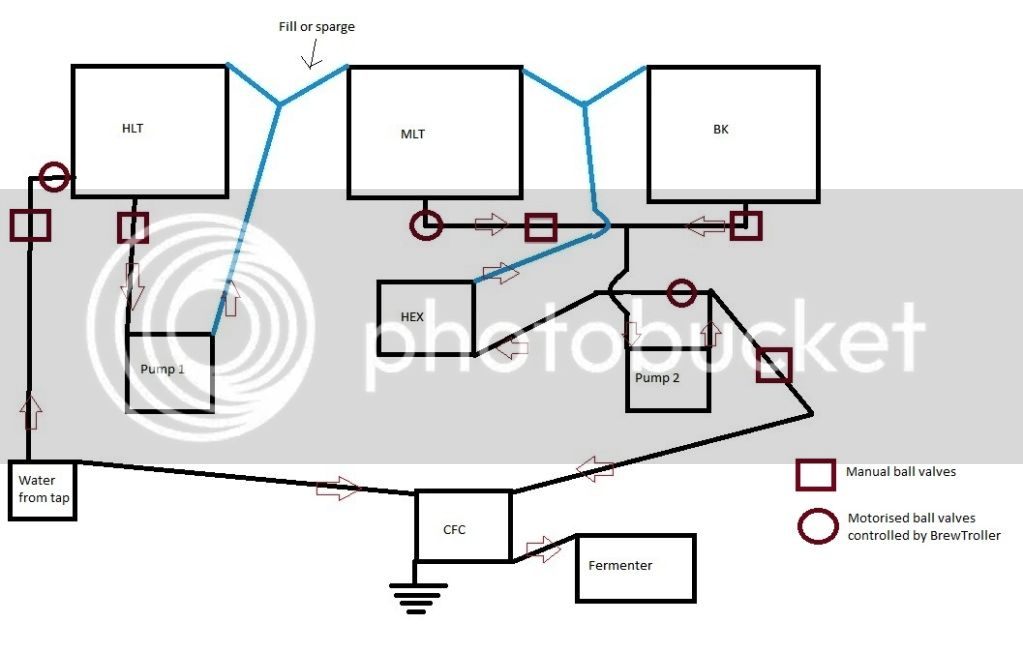

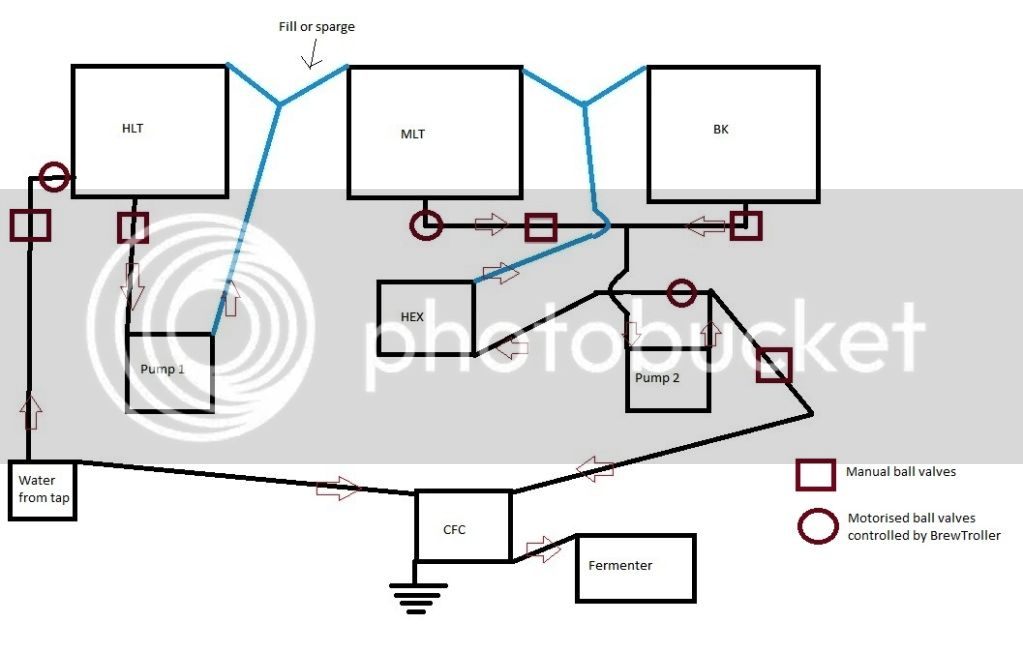

Plumbing Schematic - Thoughts?

- Thread starter cat007

- Start date

Help Support Australia & New Zealand Homebrewing Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

So a small update.

Does anyone have any ideas on how to make this more efficient?

I haven't gone into which lines are going to be hard lines and which are going to be soft (silicone?). I'm guessing any lines that go into removable items such as the HLT, MLT or BK should be soft as they'll be easier to remove/move around?

I have the pump from the HLT set to recirculate the water around the HLT while it's being heated as I've had problems with hot/cold spots in the past.

The motorised ball valves that will be controlled by brewtroller do not have a manual override hence why there's a manual ball valve in place as a failsafe incase something goes wrong.

Any suggestions are greatly appreciat

Does anyone have any ideas on how to make this more efficient?

I haven't gone into which lines are going to be hard lines and which are going to be soft (silicone?). I'm guessing any lines that go into removable items such as the HLT, MLT or BK should be soft as they'll be easier to remove/move around?

I have the pump from the HLT set to recirculate the water around the HLT while it's being heated as I've had problems with hot/cold spots in the past.

The motorised ball valves that will be controlled by brewtroller do not have a manual override hence why there's a manual ball valve in place as a failsafe incase something goes wrong.

Any suggestions are greatly appreciat

Similar threads

- Replies

- 1

- Views

- 486

- Replies

- 4

- Views

- 2K

- Replies

- 5

- Views

- 2K