Update #27: New HERMS vessel

More details on blog here.

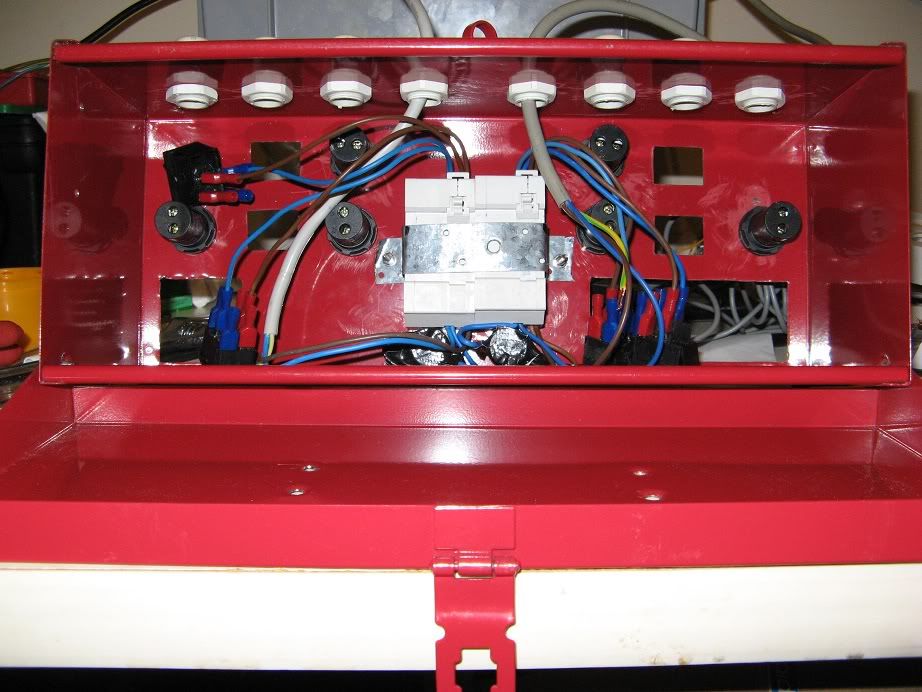

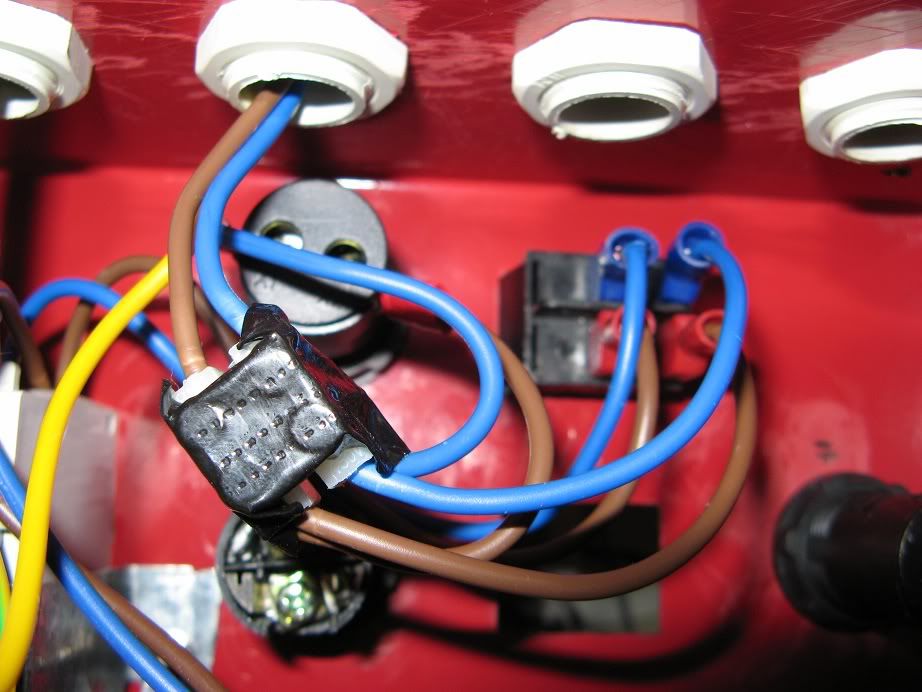

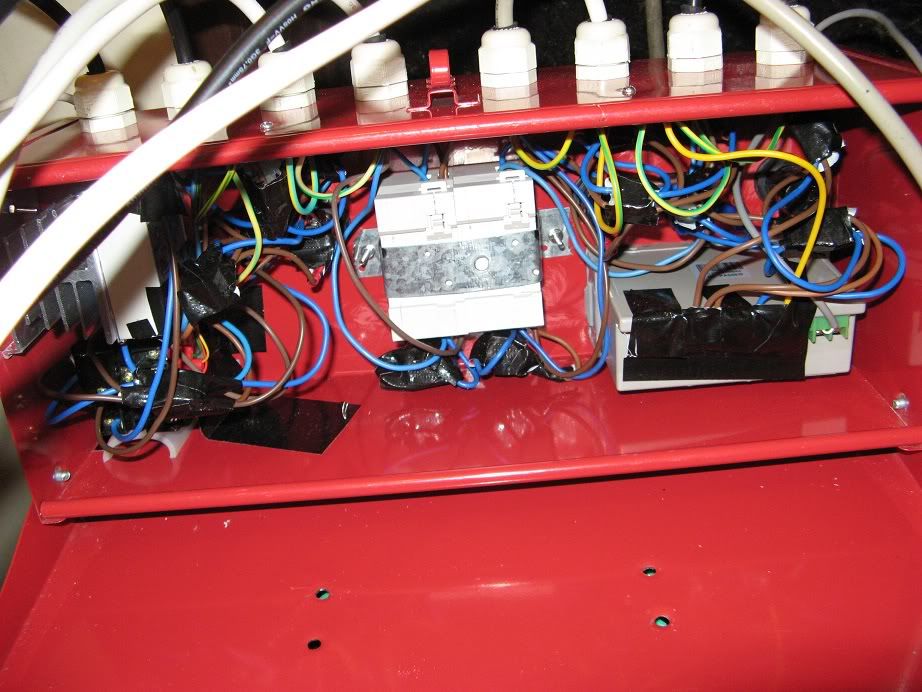

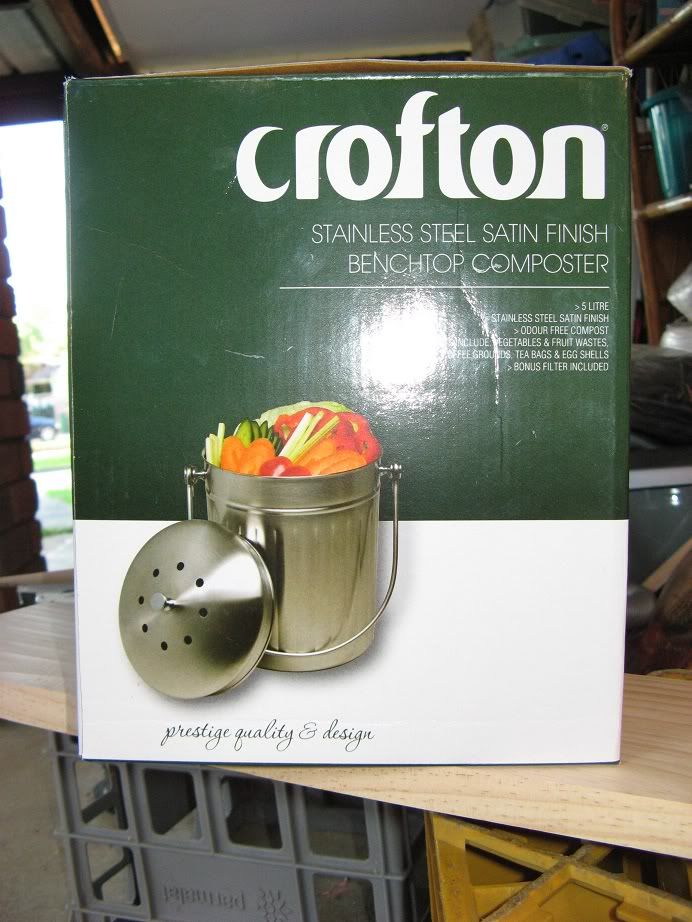

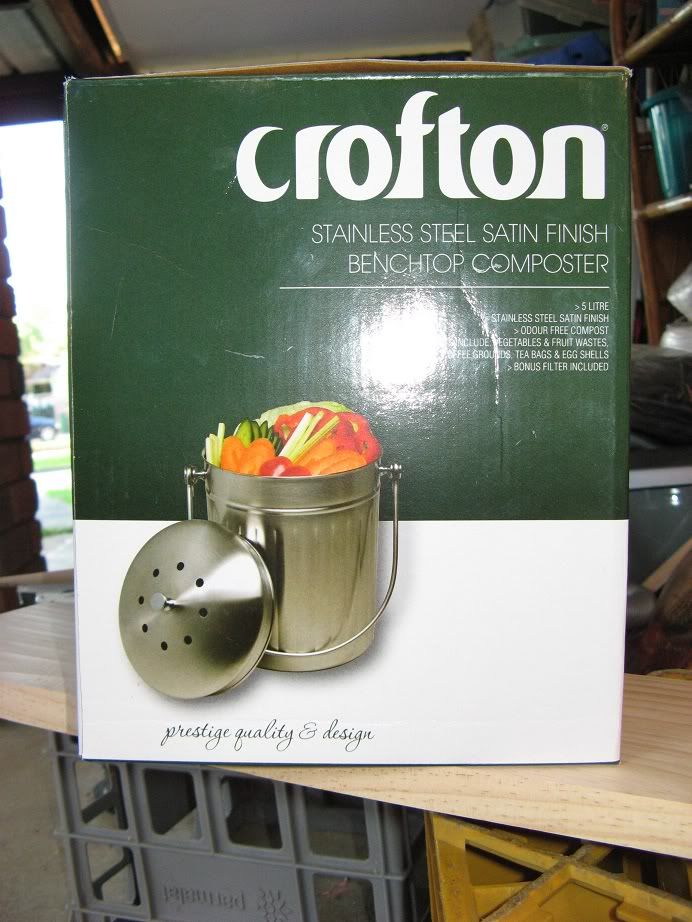

The plastic-cooler HERMS vessel worked OK, but didn't tolerate being (repeatedly) dropped on the floor, so while I was considering what to do about the HERMS container, Aldi had some stainless 'compost buckets' on special.

(Local Aldi's still have lots of these in stock, $24 each, so I expect they'll be discounted soon).

The trusty TCT hole-saw was used to make the hole in the base of the bucket for the element:

Since the element was a bit larger than the 32mm hole, it needed to be enlarged some:

A grinding-stone attached to the cordless drill, which made the process much quicker:

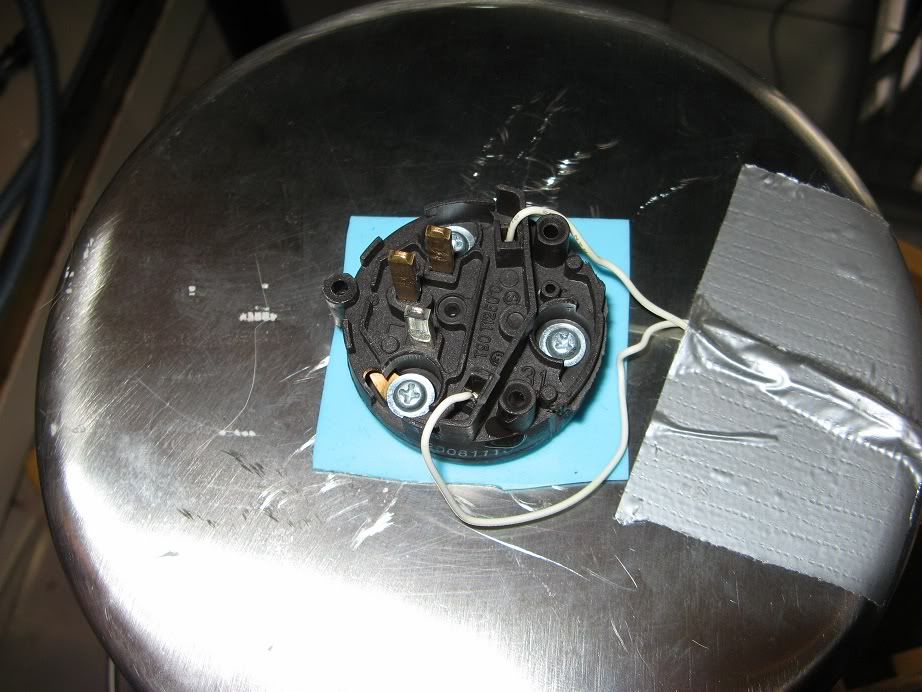

Element removed from our old kitchen kettle, once it was removed from the kettle-housing and the plastic trimmed down a little:

The gasket from the kettle-element was used to measure the hole and hold the element and mount in place:

More details on blog here.

The plastic-cooler HERMS vessel worked OK, but didn't tolerate being (repeatedly) dropped on the floor, so while I was considering what to do about the HERMS container, Aldi had some stainless 'compost buckets' on special.

(Local Aldi's still have lots of these in stock, $24 each, so I expect they'll be discounted soon).

The trusty TCT hole-saw was used to make the hole in the base of the bucket for the element:

Since the element was a bit larger than the 32mm hole, it needed to be enlarged some:

A grinding-stone attached to the cordless drill, which made the process much quicker:

Element removed from our old kitchen kettle, once it was removed from the kettle-housing and the plastic trimmed down a little:

The gasket from the kettle-element was used to measure the hole and hold the element and mount in place: