Rinsing yeast is a technique used to 'wash' the yeast/trub slurry found on the bottom of the fermentor after the beer has been removed. The 'cleaned' yeast can be pitched directly into a new batch of beer, or saved for later re-use. I've used the term 'rinsing' (as used in the recently published 'Yeast' book) to differentiate between 'washing' the yeast in water to remove trub and debris from 'acid-washing', a process used to to eliminate biological contaminants.

This process was described very well by chiller in this AHB forum thread some years ago, but as an additional starting point, there are some photos in the Yeast Rinsing Experiment which show the difference between yeast and trub.

While the process of yeast rinsing is dependent on the yeast-strain, wort composition and what (if any) fininings were used, the basic process relies on the fact that the yeasty-trub will form three distinct layers when left to settle:

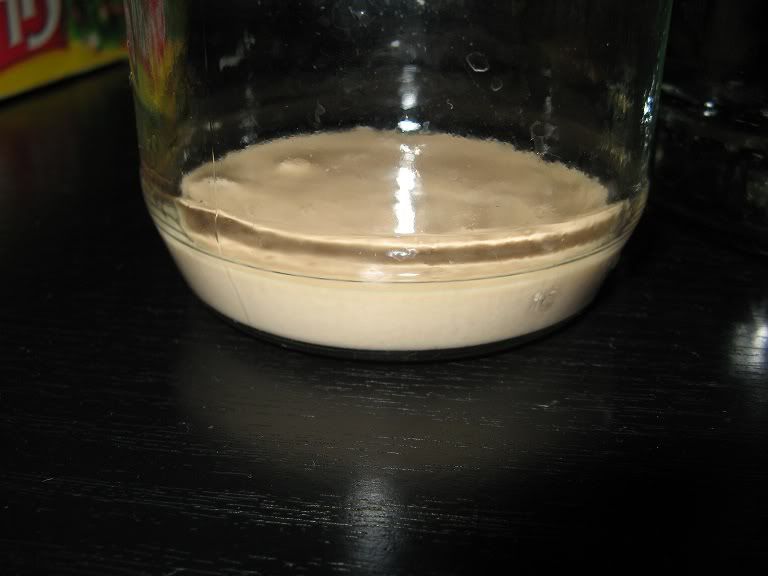

Here you can see the fermentor-dregs of a dark UK-style ale. The top clear layer of left-over beer, the creamy-yeasty middle layer, and then the trub (protiens, break material and other debris) on the bottom. The process of rinsing the yeast aims to retain only the middle layer of yeast and discard the other two layers, especially the trub and debris.

I wash my yeast in (~400ml) glass pickle jars, they can be easily heat-sterilized (in a pressure cooker or boiled in a large pot) and boiling water can be tipped directly into them to enhance the sanitation procedures. Ideally sterile distilled water should be used for yeast washing, however I use plain boiled and cooled tap-water (here in Melbourne the water is very soft and contains few minerals, but if you live in an area with hard water it may be a good idea to use treated or even bottled water). When working with yeast try to keep the equipment and procedures as clean and sterile as possible, and if possible keep the temperature constant, don't shock the yeast by tipping in water too cold or hot. I try to pre-boil the water and seal the jars a day or two in advance so that the yeast and the water will be the same temperature.

Here is the trub in the bottom of the fermetor after a recently brewed Australian Ale (using Coopers re-cultured yeast):

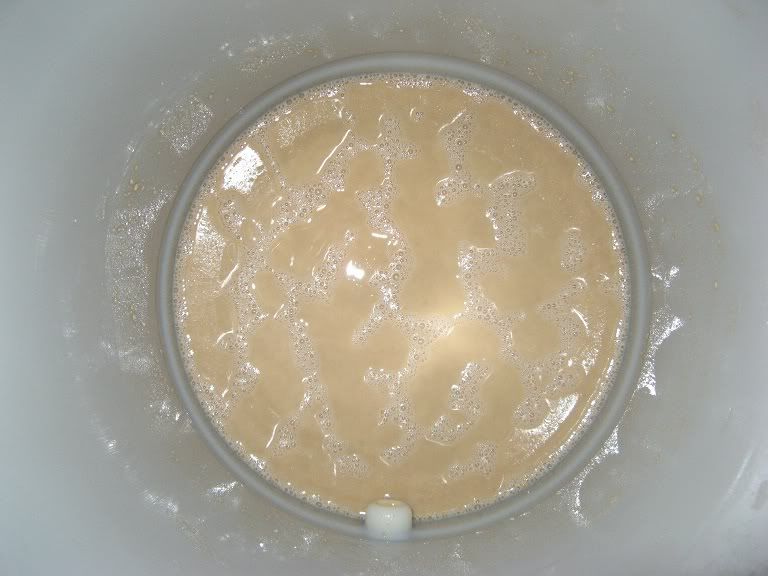

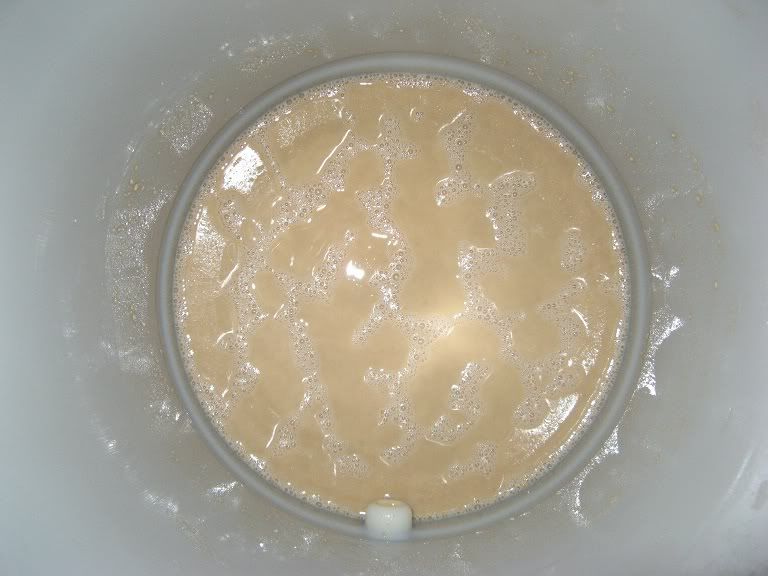

Add a jar full of cooled-boiled water (approx 400ml) and shake/swirl and mix it around and it should look like this:

Let the yeasty-liquid-trub settle for 10 to 15mins, and then the first step of the rinsing process is to decant the majority of the liquid into the rinsing-jars, but leaving behind any large bits of gunk, break material, hop or other debris:

Depending how much beer was left behind, how much yeast and how much trub you have, you should easily be able to fill 1 or 2 jars. Generally yeast rinsed from one jar is enough to pitch into a new batch of beer, but I also wanted to save some for later re-use, so I ended up with 2 jars full of yeasty-trub and the left overs in the fermentor shown above:

This process was described very well by chiller in this AHB forum thread some years ago, but as an additional starting point, there are some photos in the Yeast Rinsing Experiment which show the difference between yeast and trub.

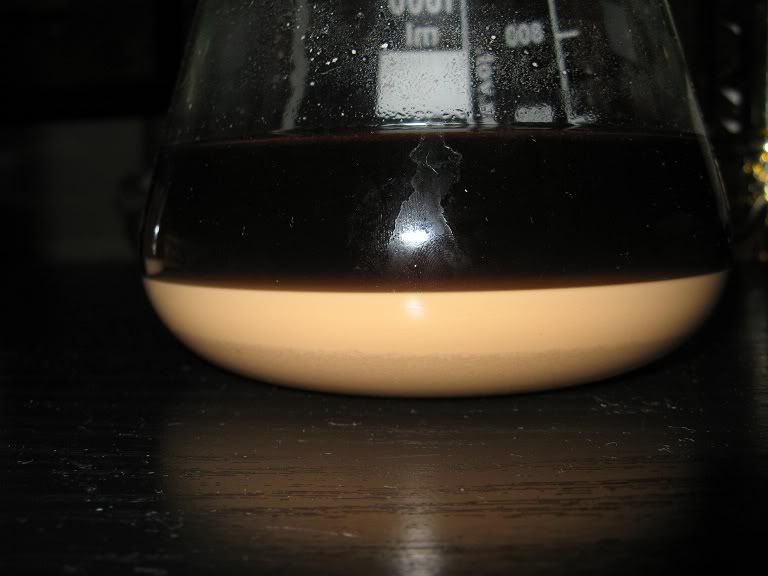

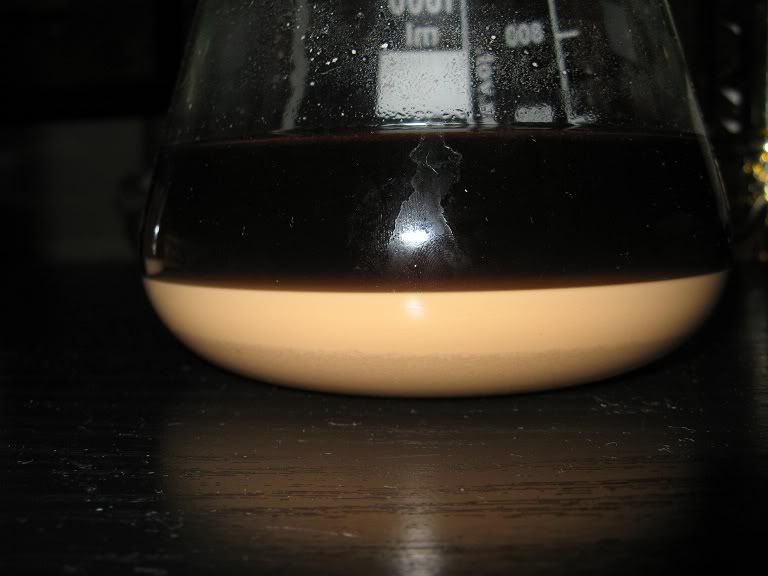

While the process of yeast rinsing is dependent on the yeast-strain, wort composition and what (if any) fininings were used, the basic process relies on the fact that the yeasty-trub will form three distinct layers when left to settle:

Here you can see the fermentor-dregs of a dark UK-style ale. The top clear layer of left-over beer, the creamy-yeasty middle layer, and then the trub (protiens, break material and other debris) on the bottom. The process of rinsing the yeast aims to retain only the middle layer of yeast and discard the other two layers, especially the trub and debris.

I wash my yeast in (~400ml) glass pickle jars, they can be easily heat-sterilized (in a pressure cooker or boiled in a large pot) and boiling water can be tipped directly into them to enhance the sanitation procedures. Ideally sterile distilled water should be used for yeast washing, however I use plain boiled and cooled tap-water (here in Melbourne the water is very soft and contains few minerals, but if you live in an area with hard water it may be a good idea to use treated or even bottled water). When working with yeast try to keep the equipment and procedures as clean and sterile as possible, and if possible keep the temperature constant, don't shock the yeast by tipping in water too cold or hot. I try to pre-boil the water and seal the jars a day or two in advance so that the yeast and the water will be the same temperature.

Here is the trub in the bottom of the fermetor after a recently brewed Australian Ale (using Coopers re-cultured yeast):

Add a jar full of cooled-boiled water (approx 400ml) and shake/swirl and mix it around and it should look like this:

Let the yeasty-liquid-trub settle for 10 to 15mins, and then the first step of the rinsing process is to decant the majority of the liquid into the rinsing-jars, but leaving behind any large bits of gunk, break material, hop or other debris:

Depending how much beer was left behind, how much yeast and how much trub you have, you should easily be able to fill 1 or 2 jars. Generally yeast rinsed from one jar is enough to pitch into a new batch of beer, but I also wanted to save some for later re-use, so I ended up with 2 jars full of yeasty-trub and the left overs in the fermentor shown above: