Hey all

So here's a little build thread of my brew rig 2.0.

Currently using a 2 tier 3 vessel system:

New system incorperates a BrewTroller, automatic ball valves, HERMS, and lots of lights lol

Main parts are:

19meter 1/2" copper HERMS coil.

2 x 3500watt elements in the HLT, which is where the HERMS coil resides.

70L HLT, 100L MLT and 70L boil kettle.

2 x magnetic pumps

Big 500x300x250mm enclosure

Open Source Control Systems BrewTroller DX1

Lots of relays.

Air pump for bubbler volume measuring system for HLT and MLT

Boil kettle is heated by a 32 jet mongolian burner - but I'll probably plug some of the holes as it's a bit too powerful.

Pics of the build so far:

HERMS coil:

Started making a false bottom for MLT out of the end of a stainless sink bench and by cutting slots:

Enclosure front panel cut out:

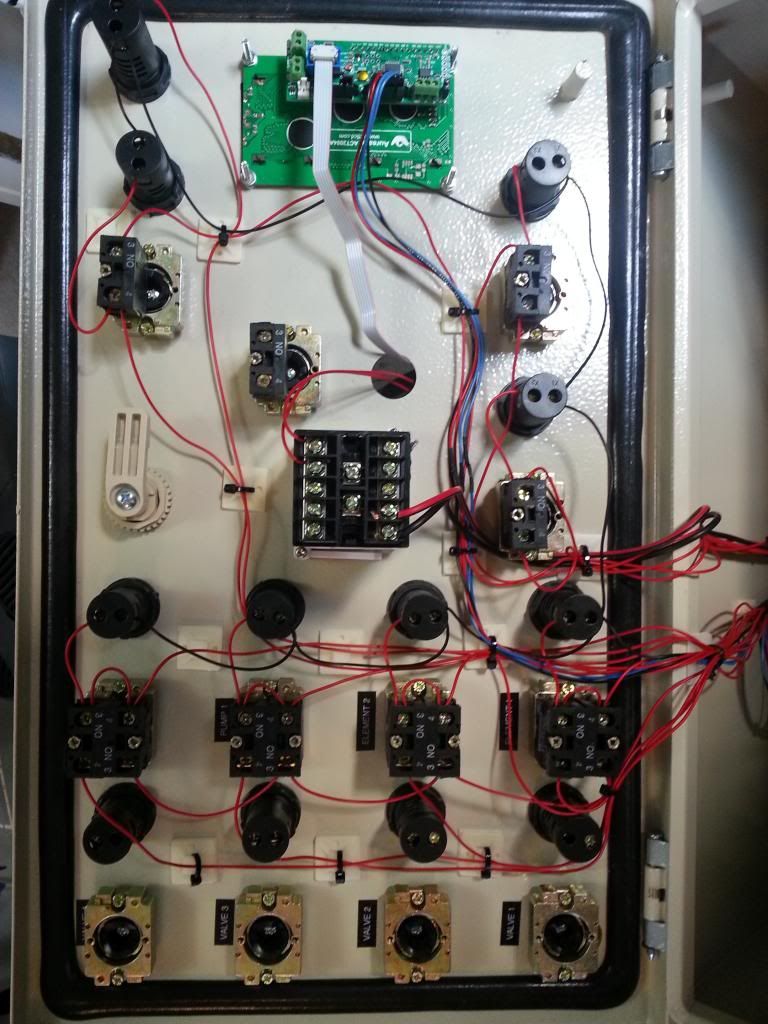

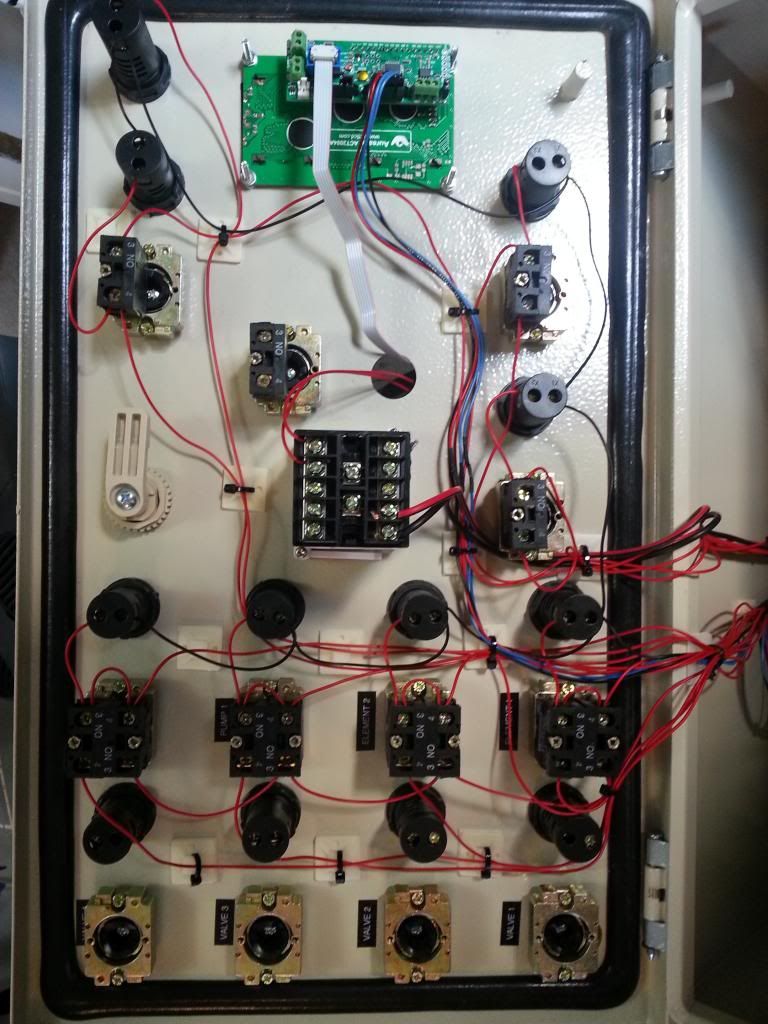

Almost everything install on front panel:

Back of front panel:

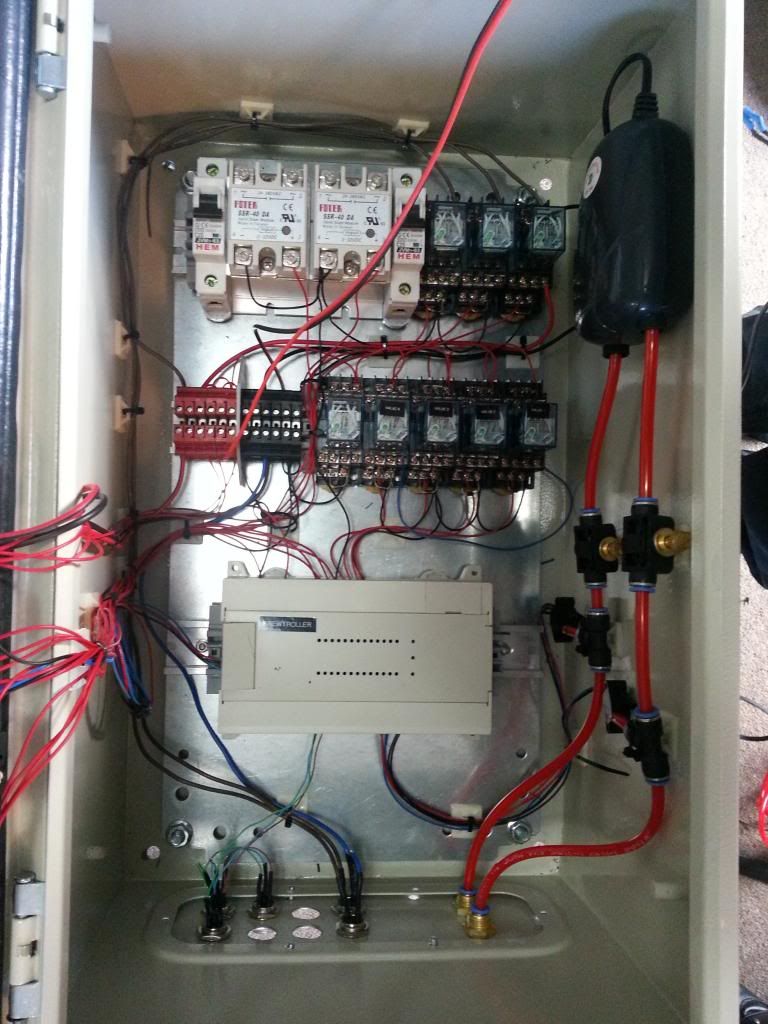

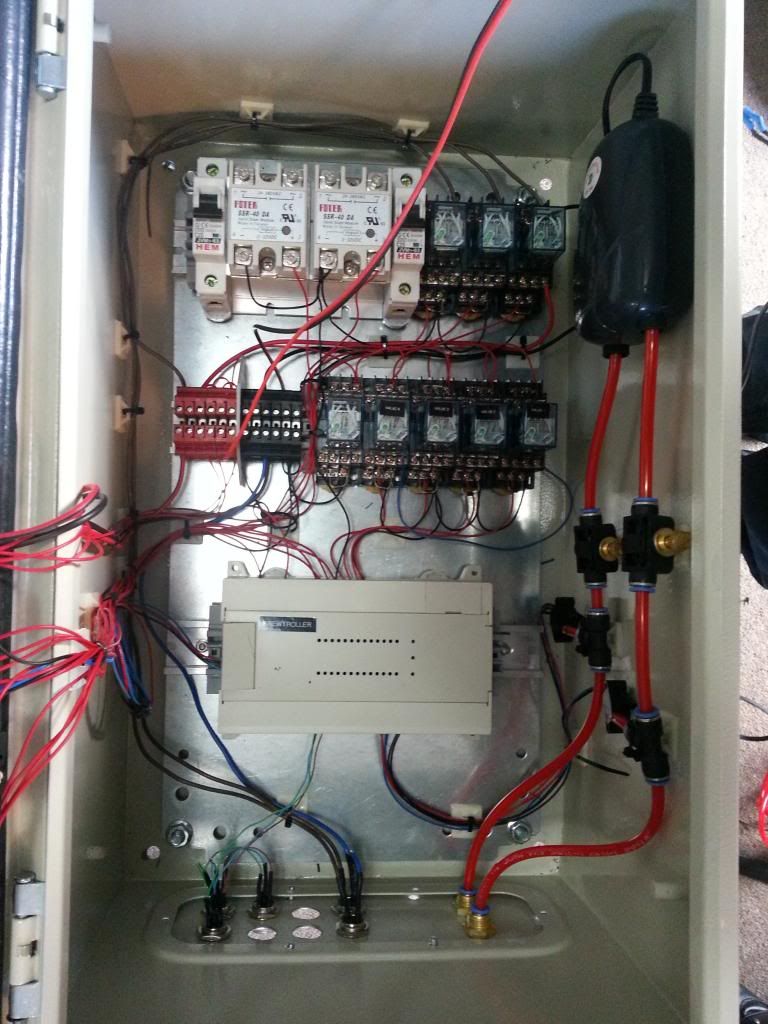

Inside the enclosure - I've since moved the SSR's to the top of the inside of the enclosure as the circuit breakers were blocking air flow too much:

Frame built:

Plumbing mock up without motorised ball valves - in mash mode:

More to come.....

So here's a little build thread of my brew rig 2.0.

Currently using a 2 tier 3 vessel system:

New system incorperates a BrewTroller, automatic ball valves, HERMS, and lots of lights lol

Main parts are:

19meter 1/2" copper HERMS coil.

2 x 3500watt elements in the HLT, which is where the HERMS coil resides.

70L HLT, 100L MLT and 70L boil kettle.

2 x magnetic pumps

Big 500x300x250mm enclosure

Open Source Control Systems BrewTroller DX1

Lots of relays.

Air pump for bubbler volume measuring system for HLT and MLT

Boil kettle is heated by a 32 jet mongolian burner - but I'll probably plug some of the holes as it's a bit too powerful.

Pics of the build so far:

HERMS coil:

Started making a false bottom for MLT out of the end of a stainless sink bench and by cutting slots:

Enclosure front panel cut out:

Almost everything install on front panel:

Back of front panel:

Inside the enclosure - I've since moved the SSR's to the top of the inside of the enclosure as the circuit breakers were blocking air flow too much:

Frame built:

Plumbing mock up without motorised ball valves - in mash mode:

More to come.....