citizensnips

Well-Known Member

- Joined

- 9/7/07

- Messages

- 769

- Reaction score

- 127

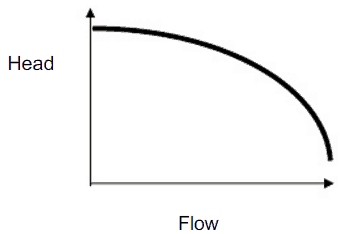

Trying to decide between the two Keg King pumps for a new system. The biggest requirement on the pump will be pushing up to 45L of wort into a conical fermenter from the bottom port up. So I'm looking at 45L of hydrostatic pressure towards the end of transfer.

For any of those who know pump maths (I'm weak here) please enlighten me on which pump I should buy,

The MKII With specs of

Voltage: 220-240 at 50-60hz

Max Head: 3.4m

Max Flow: 19L/min

Fittings: 1/2 BS

and 65W with

Voltage: 220-240 at 50-60hz

Power rating: 65w

Max Head: 6.5m

Max Flow: 52L/min

Wiring: AU Standard 10amp plug

Fittings: 3/4" BSP

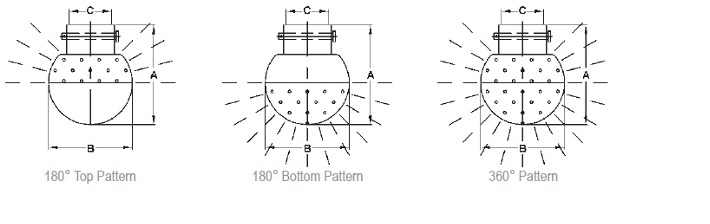

For the record I'll be running 1/2" fittings and hoses of everything as well as my kettle will sit virtually at the same height as the inlet on the conical it is running to (with the pump sitting below the level of wort of course).

Any advice would be much appreciated for a man finally buying a pump after 11 years of home brewing.

Cheers

For any of those who know pump maths (I'm weak here) please enlighten me on which pump I should buy,

The MKII With specs of

Voltage: 220-240 at 50-60hz

Max Head: 3.4m

Max Flow: 19L/min

Fittings: 1/2 BS

and 65W with

Voltage: 220-240 at 50-60hz

Power rating: 65w

Max Head: 6.5m

Max Flow: 52L/min

Wiring: AU Standard 10amp plug

Fittings: 3/4" BSP

For the record I'll be running 1/2" fittings and hoses of everything as well as my kettle will sit virtually at the same height as the inlet on the conical it is running to (with the pump sitting below the level of wort of course).

Any advice would be much appreciated for a man finally buying a pump after 11 years of home brewing.

Cheers