ThatKiwiFella

Well-Known Member

- Joined

- 18/11/10

- Messages

- 60

- Reaction score

- 1

My Keezer & Temperature Controller (STC-1000) build

Hi all, this is my first proper post so hang in there and go easy Hopefully there are some useful pointers...

Hopefully there are some useful pointers...

It is fair to say that a lot of the information that I used to achieve building my temp controller came from here, but maybe there will be a couple of things new or different to help people in the future.

Please, use the search function and you’ll have all the info you need – my advice is to read more than one thread and look at multiple wiring diagrams as one may make more sense to you than others – plus you’ll find a consensus on good practices. Mine is not perfect and there are things I would consider changing if I am to make another.

Disclaimer: I am not an electrician! I am electrically minded and have done a few projects for myself in the past. The below info is my best attempt to create a functional and safe tool for assisting my brewing. if you are not confident, cannot read electrical diagrams or don’t understand wiring the please, for the safety of yourself, family & friends, DO NOT attempt any wiring or at the least get a sparky to check your work BEFORE flicking the on switch.

I ordered my STC-1000 off ebay, it arrived after about 2 weeks and then I set about wiring it up.

Jaycar & Bunnings had most of the goods I needed and I have included my shopping list at the bottom of this.

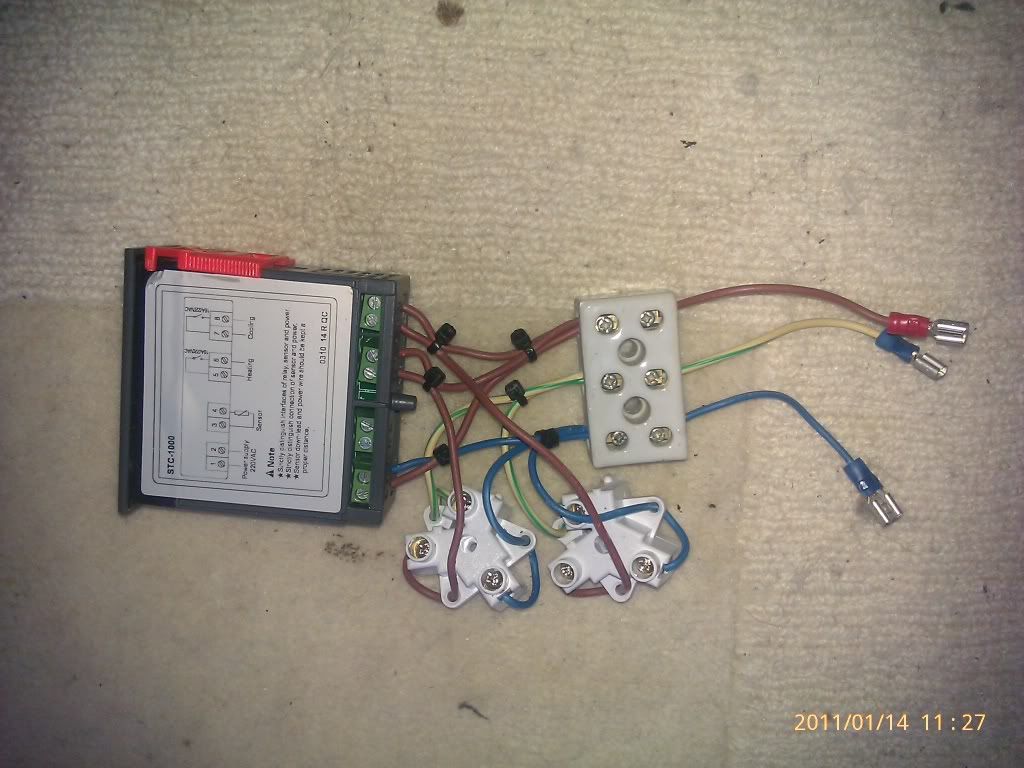

^An idea of what I started with (less a few wires, 1 plug, etc).

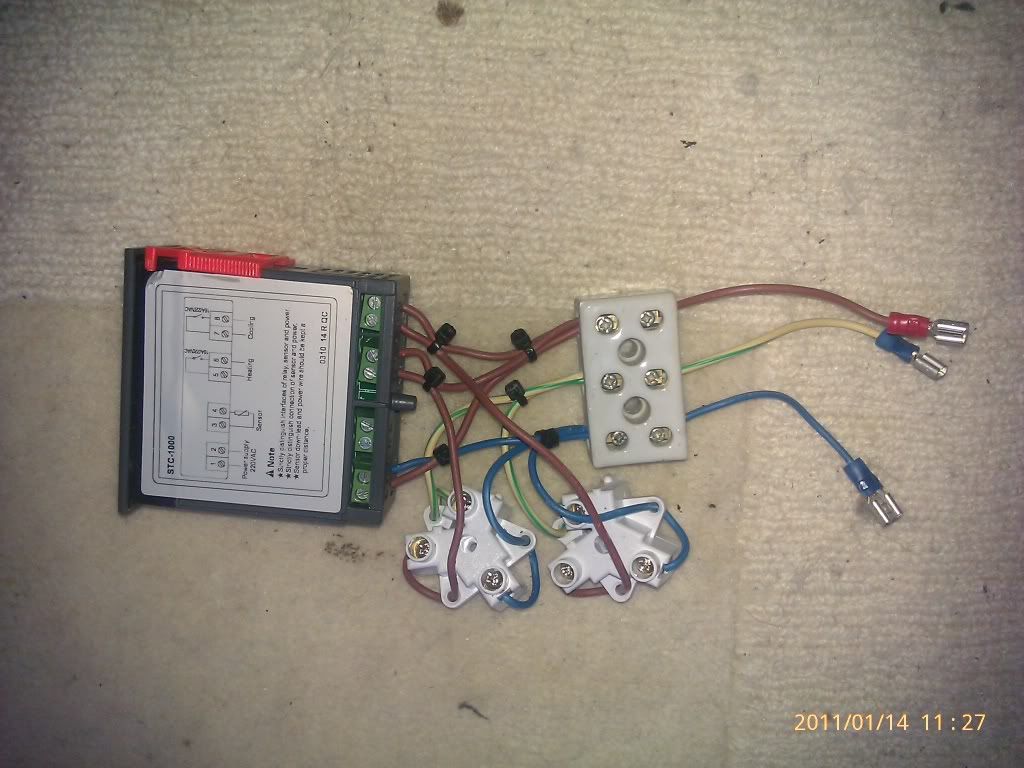

^After wiring I got to here (no probe wired yet). I went for a ceramic 240v joiner, but that is only because jcar were out of plastic ones of a decent ampage.

^I used the back plate of the STC as an outline for the hole size and I used a drill to make holes in the corners of the outline for the STC-1000. I then used a Drill Saw bit to cut out the panel (I reckon a hack saw blade might be better...?). I did the same for the rear plug and used a hole saw bit for the Heating and Cooling plugs. The breather hole exists as I drilled too close to the unit to fit a power outlet... A mistake that I think may actually have led to advantages (air flow for lower internal temp levels). I also placed heat shrink over the female connects to the power plug for added insulation. Hot glue holds the fly mesh in place on the grommet.

After sealing everything I was left with the below.

It has been running, in my garage, with my freezer connected for about 3 weeks now, without any problems. I did find there were temp overshoots (not from data logging, just observation, as I set it at 2 degrees C and could walk in and find it at 0.9 degrees C) however after reducing the desired temp to 1 degree it appears to be more stable (even given the 42 degrees outside which makes inside the tin garage a fair bit warmer!).

Edit: damned Autocorrect!

Hi all, this is my first proper post so hang in there and go easy

It is fair to say that a lot of the information that I used to achieve building my temp controller came from here, but maybe there will be a couple of things new or different to help people in the future.

Please, use the search function and you’ll have all the info you need – my advice is to read more than one thread and look at multiple wiring diagrams as one may make more sense to you than others – plus you’ll find a consensus on good practices. Mine is not perfect and there are things I would consider changing if I am to make another.

Disclaimer: I am not an electrician! I am electrically minded and have done a few projects for myself in the past. The below info is my best attempt to create a functional and safe tool for assisting my brewing. if you are not confident, cannot read electrical diagrams or don’t understand wiring the please, for the safety of yourself, family & friends, DO NOT attempt any wiring or at the least get a sparky to check your work BEFORE flicking the on switch.

I ordered my STC-1000 off ebay, it arrived after about 2 weeks and then I set about wiring it up.

Jaycar & Bunnings had most of the goods I needed and I have included my shopping list at the bottom of this.

^An idea of what I started with (less a few wires, 1 plug, etc).

^After wiring I got to here (no probe wired yet). I went for a ceramic 240v joiner, but that is only because jcar were out of plastic ones of a decent ampage.

^I used the back plate of the STC as an outline for the hole size and I used a drill to make holes in the corners of the outline for the STC-1000. I then used a Drill Saw bit to cut out the panel (I reckon a hack saw blade might be better...?). I did the same for the rear plug and used a hole saw bit for the Heating and Cooling plugs. The breather hole exists as I drilled too close to the unit to fit a power outlet... A mistake that I think may actually have led to advantages (air flow for lower internal temp levels). I also placed heat shrink over the female connects to the power plug for added insulation. Hot glue holds the fly mesh in place on the grommet.

After sealing everything I was left with the below.

It has been running, in my garage, with my freezer connected for about 3 weeks now, without any problems. I did find there were temp overshoots (not from data logging, just observation, as I set it at 2 degrees C and could walk in and find it at 0.9 degrees C) however after reducing the desired temp to 1 degree it appears to be more stable (even given the 42 degrees outside which makes inside the tin garage a fair bit warmer!).

Edit: damned Autocorrect!