Truman42

Well-Known Member

- Joined

- 31/7/11

- Messages

- 3,973

- Reaction score

- 608

You want to be able to unscrew the lid to pull your coil out to flush and hang it upside down to drain, and your going to get nasties growing inside your coil which will taste your beer.Parks said:Is anyone putting coolant or other in theirs to increase the boiling point and/or keep the liquid "less nasty".

I'm thinking it would be good if I had a preservative of some sort in it so that I didn't have to empty it each time (and leave it mounted to my brew stand)

-- EDIT --

I just remembered the PVC pipe probably won't handle anything higher than 100 degrees so should be very careful.

Therefore just as easy to empty the water out of the pipe after use. Then refill on brew day. My lid is a ***** to screw on because I didnt make the holes in the right spot for the coil to pass through. It wants to cross thread all the time so I usually just screw it on 1/2 a turn and leave it at that.

if I made one again I would have the lid just slide on and off with one of those joining collars.

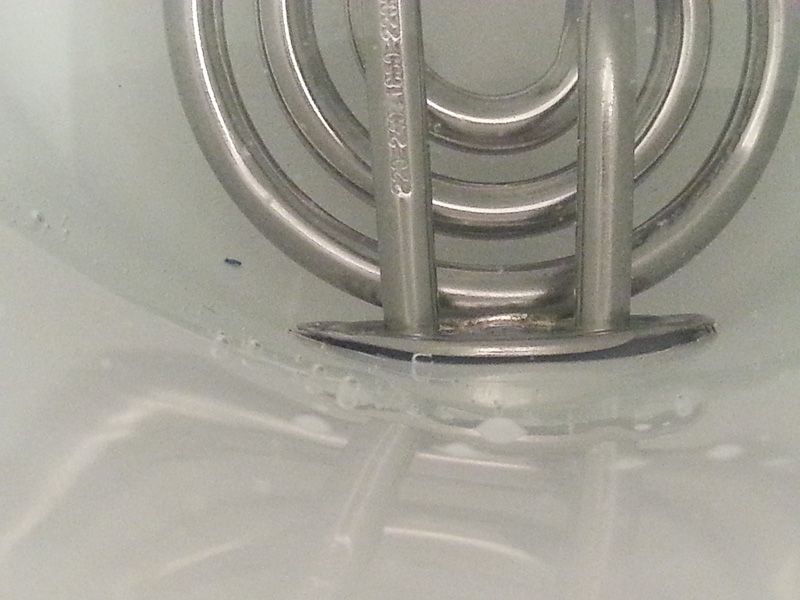

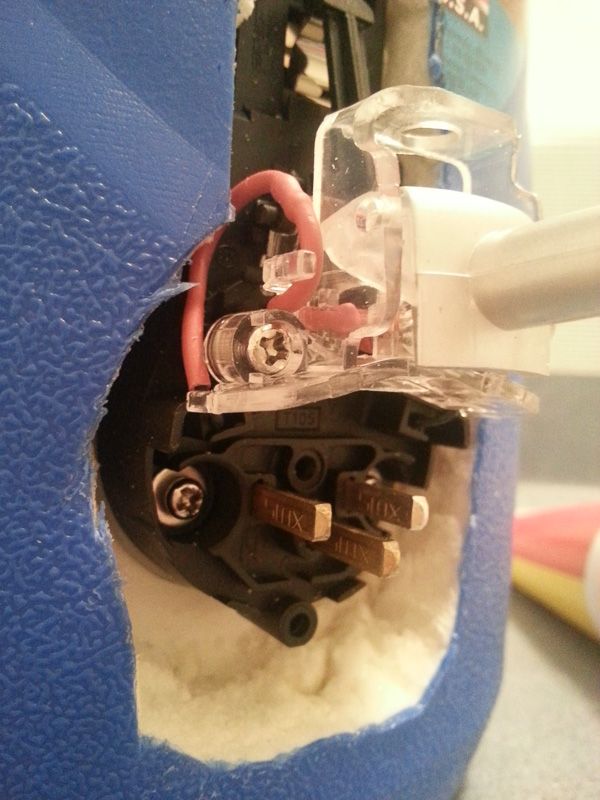

Like this