enoch

Well-Known Member

- Joined

- 29/1/06

- Messages

- 563

- Reaction score

- 55

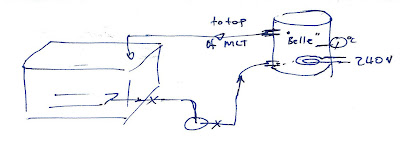

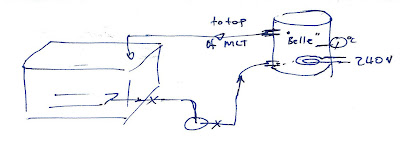

Have been thinking about a cheap RIMS chamber using a plastic kettle which remains open at the top. More for doing step mashes rather than RIMS per se.

Would have a 1/2 inch bulkhead fitting near the bottom as an input for wort coming from the MLT via a pump and a 3/4 fitting near the top which would gravity flow back into the top of the MLT.

Would need the larger fitting on the top to make sure the kettle didn't overflow. May make the spout of the kettle hang over edge of MLT to take any runoff.

Your thoughts would be appreciated.

Would have a 1/2 inch bulkhead fitting near the bottom as an input for wort coming from the MLT via a pump and a 3/4 fitting near the top which would gravity flow back into the top of the MLT.

Would need the larger fitting on the top to make sure the kettle didn't overflow. May make the spout of the kettle hang over edge of MLT to take any runoff.

Your thoughts would be appreciated.