Well, not strictly true. It gets complicated and I am not a physicist... But, you can have two pumps on a tee where all inlets and outlets are the same, in which case you *might* have a bottleneck and reduced flow (greater than 1 pump less than 2 pump), or, you may get up to double the flow, with a doubling of fluid velocity. It depends on the pump parameters I believe, ie suction and/or head pressure depending on whether the tee is in front or behind the pumps.

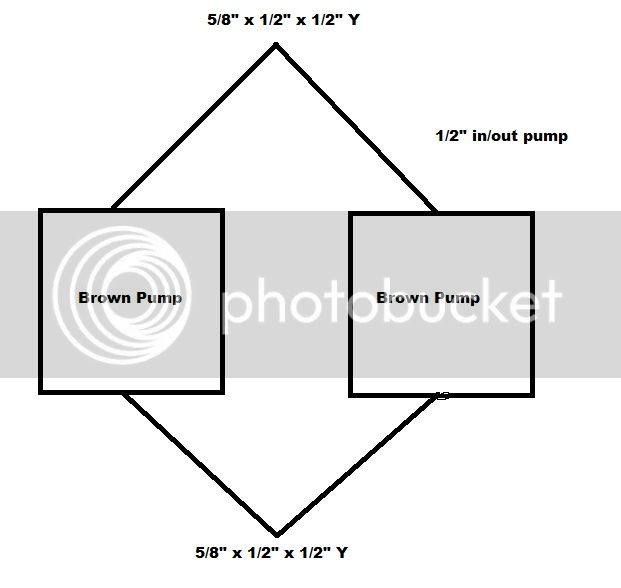

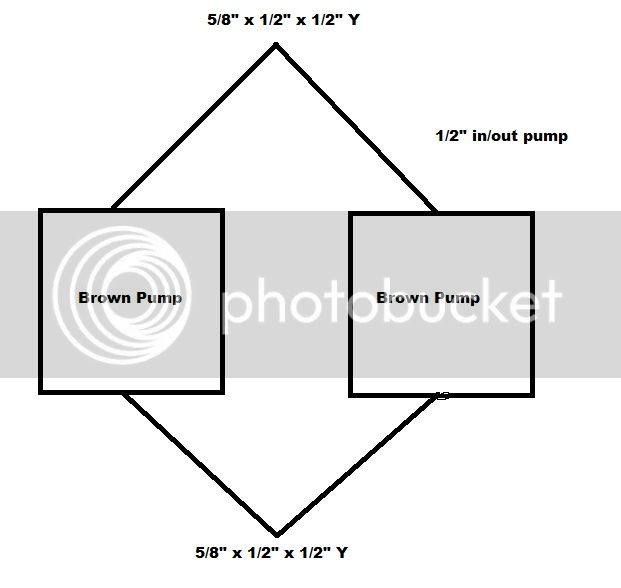

To ensure you don't have bottleneck issues, if you have two pumps with 1/2" inlet/outlets, then the tee you want would have two pump inlets at 1/2" and your 'main suction inlet' to have a cross sectional area equal to 2 times 1/2", whatever that is.

Anyone please feel free to correct me if I am wrong and I will change my crappy maths:

d = 1/2" = 12.7mm

r=d/2

r=6.35mm

a=pi*r^2 = 3.14159*(6.35)^2

a=126.67mm^2

to prevent any bottlenecks, width of main suction inlet is a*2

a*2=253.35mm^2.

What diameter tubing is this?

a = pi*(r^2) let a=253.35mm^2

253.35/2 = 3.14159*(r^2)

253.35/3.14159 = (r^2)

r^2 = 80.64

sqrt(r^2)=r

sqrt(80.64)=8.979mm

diameter = r*2

8.979*2 = 17.958mm

17.958mm is 0.707 inches

5/8" is 15.875mm, which is pretty close, and probably 'not a problem' for this setup.

for true prevention of a bottleneck though you'd need one a bit bigger.

3/4" is 0.75 inches, which is slightly greater than 0.707 inches, and is easier to obtain than 5/8" i think....... so 3/4" is the ideal choice for master suction/outlet lines for no bottleneck given 'doubling up' two 1/2" pump lines.

:

: