Adr_0

Gear Bod

- Joined

- 4/4/13

- Messages

- 1,776

- Reaction score

- 684

Hi Mark,Warra and I aren't disagreeing on anything, in fact neither of us is recommending any Carra Malt, that would be included to make an Amber or Dunkel Wheat.

There are two distinct elements to brewing, the science of and the art of brewing, to me the science underpins the art, a bit like architecture, you can draw anything, but the rules of engineering tells you whether or not it will stand up.

Clearly you don't have a lot of experience with hefeweizen, I would strongly recommend you start with something simple like a 50/50 wheat pilsner (spend the extra and go German, it will taste better).

If your supplier cant give you what you need - try someone else. If you have a good local HBS support them, but if you need things they don't stock, get what you need I use Brewman, but depending on where you are there are a few good choices.

If I wanted to do a Dunkel Weiss, I would go to CarraWheat in preference to CaraMunich

Add the dextrose to the kettle near the end of the boil, about 5% of the total weight of extract, for a 25L batch (end of boil) that comes to around 150g.

The mash regime is a very specialised one, it isn't necessary if you are adding dextrose, it is designed to create Glucose (dextrose) which doesn't normally happen in a mash as the Maltase is killed off before the maltose is made.

There are way too many different types of wheat beer and ways of making them for us to cover here, if you want to know way too much try this Brewing Bavarian Weissbier – all you ever wanted to know

Starting out keep it simple and enjoy the beer.

Mark

This is a great link - very good reading and goes well with Brewing With Wheat (Stan H) and German Wheat Beer (Eric W) as great wheat beer resources.

I'm curious about two things:

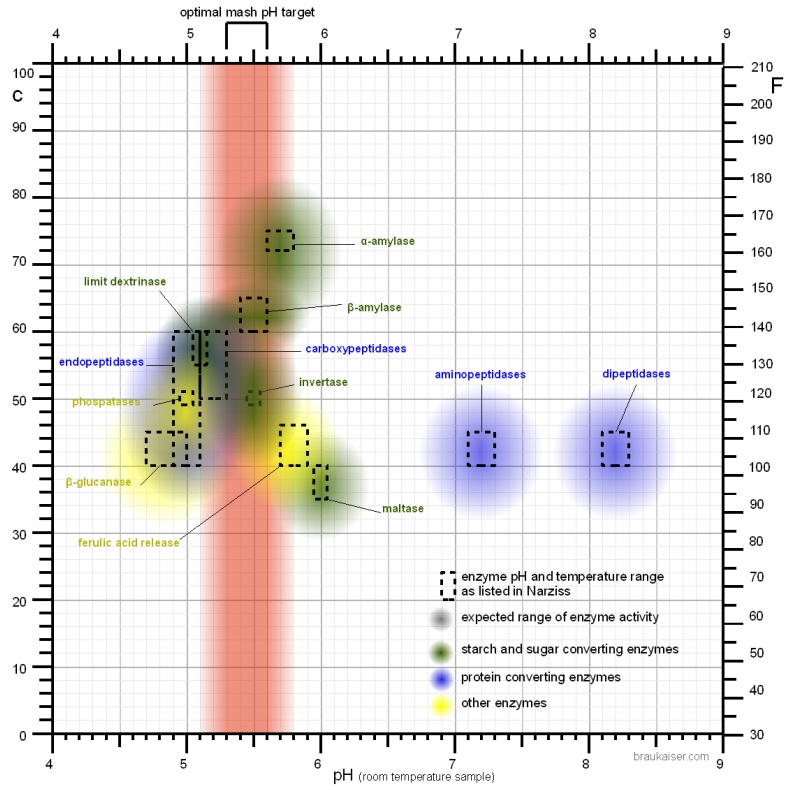

- 45°C is flagged as where maltase is most active but this is also where ferulic acid is produced. Both enzymes seem to be most active at pH 5.8-6.2. Is the intention of the article that 4VG/clove is also increased or does isoamyl acetate increase much further? Stan H's table on page 85 indicates the beer becomes less estric the longer the mash rests at this temperature.

- Since we're not Reinheitsgebot-bound, it's suggested in the article to add malt extract to the mash as availble maltose for the 45°C maltase rest, which breaks it down into glucose. Couldn't dextrose just be added at the end of the boil?

I'm not sure how accurate this is, but it seems to suggest maltase is active in the high 30's with overlap around 39-41°C, not 45°C: